News

វិច្ឆិកា . 07, 2024 06:51 Back to list

Understanding the Various Sizes of Turnbuckles for Different Manufacturers

Understanding Manufacturer Turnbuckle Sizes A Comprehensive Overview

When it comes to rigging and structural connections in engineering and construction, turnbuckles are indispensable components. These devices, primarily used to adjust the tension and length of ropes, cables, or rods, have a wide range of applications across industries. Manufacturers provide various sizes of turnbuckles to accommodate different needs, but how do you determine the right size for your project? In this article, we will delve into the critical aspects of turnbuckle sizes, including definitions, types, and the factors influencing your choice.

What is a Turnbuckle?

A turnbuckle is a mechanical device consisting of two threaded eyelets or hooks on either end and an adjustable central sleeve. By rotating the central sleeve, the distance between the eyelets can be increased or decreased, allowing for precise tension adjustments. Turnbuckles are made from durable materials such as stainless steel, alloy steel, or aluminum, ensuring they can withstand significant loads in various environments.

Types of Turnbuckles

Turnbuckles come in several configurations, including standard, closed body, and open body models. Each type has its specific applications and limitations

1. Standard Turnbuckles These are the most common types and feature a simple design. They can be used in moderate tension applications, such as securing canopies or supporting signs.

2. Closed Body Turnbuckles Ideal for high-tension applications, closed body turnbuckles offer enhanced strength and security. They encase the thread entirely, reducing wear and tear while providing a cleaner appearance.

3. Open Body Turnbuckles Similar to standard models, open body turnbuckles have exposed threads. While they are easier to adjust, they are also more vulnerable to debris and corrosion.

4. Swage Turnbuckles These turnbuckles are used in wire rope applications and provide a sleeker look. They are ideal for marine or architectural applications, where aesthetics are just as important as functionality.

manufacturer turnbuckle sizes

Selecting the Right Size Turnbuckle

Choosing the correct size for a turnbuckle involves several factors

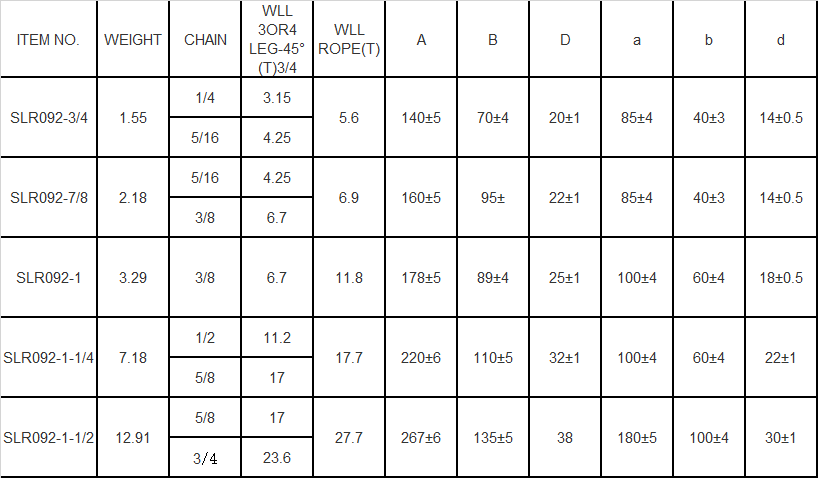

1. Load Requirements The first consideration is the load the turnbuckle must handle. Manufacturers categorize turnbuckles based on their working load limit (WLL), which indicates the maximum weight they can safely support. It’s essential to choose a turnbuckle with a WLL that exceeds your project's requirements.

2. Material Considerations Turnbuckles are typically made from different materials, each with varying strength properties. Stainless steel offers excellent resistance to corrosion, making it suitable for outdoor or marine environments. On the other hand, alloy steel may provide enhanced load-bearing capabilities but may be susceptible to rust.

3. Length and Thread Size The length of the turnbuckle is another critical factor. It should be long enough to allow for the desired adjustment without compromising the integrity of the connection. Thread size matters too; larger threads generally offer more strength but may complicate installation in tight spaces.

4. Environmental Conditions Consider the environment in which the turnbuckle will be used. For outdoor applications, corrosion-resistant materials are vital to ensure longevity. In contrast, indoor applications might prioritize cost-effectiveness over durability.

5. Regulatory Standards Depending on your industry, there may be regulatory standards governing the use of turnbuckles in certain applications. Familiarity with these regulations can guide your decision.

Conclusion

Understanding manufacturer turnbuckle sizes is crucial for anyone involved in rigging, construction, or engineering. The right turnbuckle not only ensures the safety and reliability of your projects but also enhances efficiency. By considering factors such as load requirements, material properties, and environmental conditions, you can select the ideal turnbuckle size for your specific needs. Always remember that investing in quality components will pay off in longevity and performance, making your projects safer and more successful. With the right knowledge and considerations, you can navigate the complexities of turnbuckle sizes with confidence.