News

តុលា . 15, 2024 10:08 Back to list

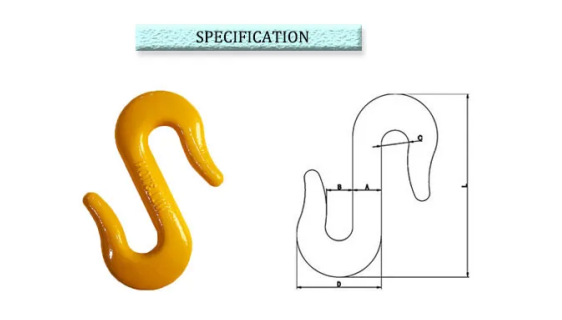

Manufacturer of High-Quality Rigging Hooks for Reliable Lifting Solutions and Heavy-Duty Applications

Understanding Manufacturer Rigging Hooks A Comprehensive Guide

In the world of construction, shipping, and heavy lifting, rigging hooks play an essential role in ensuring safety and efficiency. These hooks, often manufactured to meet strict industrial standards, are crucial components in various lifting applications. In this article, we will explore the various types of rigging hooks, their applications, and how to choose the right manufacturer for your needs.

Types of Rigging Hooks

Rigging hooks come in various designs, each tailored for specific applications. Some of the common types include

1. Snap Hooks These hooks feature a spring-loaded latch that allows for quick attachment and detachment. Snap hooks are often used in situations where rapid connection is necessary, such as in climbing and rescue operations.

2. Swivel Hooks Designed to rotate 360 degrees, swivel hooks prevent tangling of ropes and chains during lifting operations. This feature is particularly useful in situations where loads need to be maneuvered frequently.

3. Fixed Eye Hooks These hooks have a permanently attached loop (eye) for easy connection to chains or other rigging equipment. They are widely used in lifting heavy objects and are available in various sizes and weight capacities.

4. Clevis Hooks Clevis hooks come with a pin that secures the hook to a chain or strap, providing a strong and reliable connection. They are often used in heavy-duty applications, such as construction and industrial lifting.

5. Safety Hooks Similar to snap hooks, safety hooks come with additional features like locking mechanisms to prevent accidental release. These are essential in scenarios where safety is paramount, such as in rigging and lifting operations.

Applications of Rigging Hooks

Rigging hooks are used in various industries, including construction, manufacturing, transportation, and entertainment. Some specific applications include

manufacturer rigging hook

- Construction Sites In construction, rigging hooks help lift heavy materials, such as steel beams and concrete panels, facilitating the assembly of structures. - Shipping and Logistics In warehouses and shipping yards, hooks are used to handle cargo containers and pallets, ensuring safe and efficient loading and unloading. - Theatrical Productions In the entertainment industry, rigging hooks are used to suspend lighting and sound equipment, allowing versatility in stage setups. - Rescue Operations In emergency situations, snap and safety hooks are vital for quick and secure attachments when rescuing individuals from precarious situations.

Choosing the Right Manufacturer

When sourcing rigging hooks, selecting a reputable manufacturer is crucial. Here are some factors to consider

1. Quality Standards Ensure the manufacturer adheres to relevant safety standards and certifications, such as those set by the American National Standards Institute (ANSI) or the Occupational Safety and Health Administration (OSHA).

2. Material and Design Look for hooks made from materials that offer durability and strength, such as high-grade steel or aluminum. The design should also suit your specific lifting needs.

3. Product Range A manufacturer that offers a wide range of products can better accommodate your diverse rigging requirements, from different hook types to various weight capacities.

4. Reputation and Reviews Research the manufacturer's reputation in the industry. Customer reviews and testimonials can provide valuable insights into the reliability and performance of their products.

5. Customer Support A good manufacturer should provide excellent customer support, including guidance on product selection, installation, and maintenance.

Conclusion

Rigging hooks are indispensable tools in various industries, facilitating safe and efficient lifting operations. Understanding the different types of hooks and their applications, along with choosing the right manufacturer, is essential in ensuring that your rigging tasks are performed reliably and safely. By prioritizing quality and safety, you can enhance your operational efficiency while minimizing risks in the workplace.