News

វិច្ឆិកា . 03, 2024 17:13 Back to list

manufacturer g80 us forged master link

Understanding the G80 US Forged Master Link A Key Component in Rigging

In the world of rigging and lifting, safety and reliability are paramount. One integral component that supports these principles is the G80 US forged master link. This hardware is designed to connect various rigging components, ensuring that loads are lifted securely and efficiently. In this article, we’ll delve into what makes the G80 master link exceptional, its applications, and why it is essential in various industries.

What is a G80 US Forged Master Link?

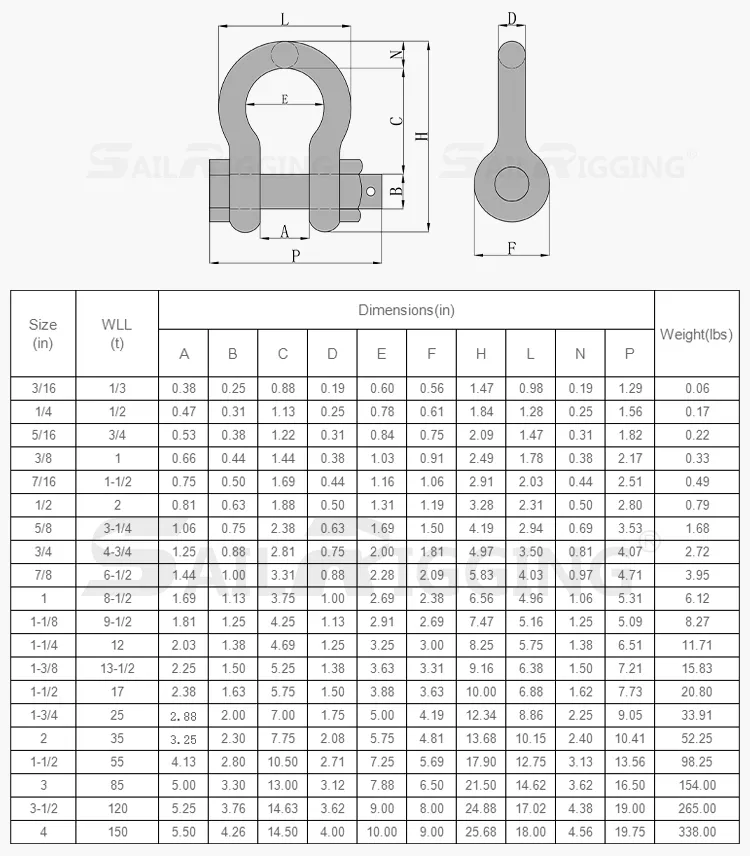

A master link is a connecting element that allows multiple straps, chains, or slings to be combined for lifting purposes. The designation “G80” signifies that the master link is made from high-quality steel, specifically rated for grade 80 applications. This grade indicates a minimum breaking strength of 8 times the working load limit (WLL), making it suitable for heavy-duty applications.

Forged from high-strength alloy steel, G80 master links are engineered for toughness and durability. The forging process enhances the structural integrity of the metal, allowing it to withstand the demanding conditions often encountered during lifting operations. Furthermore, these links are typically heat-treated to optimize their strength and performance, ensuring they can handle repeated loads without compromising safety.

Applications of G80 Master Links

G80 US forged master links are versatile and are used in a wide range of applications across various industries. Common uses include

1. Construction In construction sites, G80 master links are critical for lifting heavy beams, steel plates, and other materials. Their strength and reliability help ensure that loads remain secure while being hoisted.

2. Shipping and Logistics In the shipping industry, these master links are employed to secure cargo during transport. By providing a robust connection between chains and slings, they help prevent accidents during loading and unloading.

manufacturer g80 us forged master link

4. Oil and Gas Industry In this sector, G80 master links are vital for rigging in challenging environments. Their durability ensures they can withstand harsh weather conditions and heavy loads.

Why Choose G80 Master Links?

1. Safety The primary reason for utilizing G80 master links is safety. Their high strength-to-weight ratio and rigorous testing standards minimize the risk of failure during lifting operations.

2. Durability G80 master links are designed to last. They resist wear and fatigue better than lower-grade alternatives, ensuring long-term reliability.

3. Versatility Their compatibility with various chains and slings makes G80 master links adaptable to multiple rigging needs, ranging from overhead lifting to assembling complex structures.

4. Industry Standards Being manufactured in accordance with industry standards ensures G80 master links meet rigorous safety and performance requirements, giving users peace of mind.

Conclusion

In conclusion, the G80 US forged master link is an essential component in the realm of rigging and lifting. Its robust construction, high strength, and versatile application make it a preferred choice for professionals across numerous industries. By investing in high-quality G80 master links, operators can enhance safety, efficiency, and reliability in their lifting operations, ultimately leading to better productivity and reduced risk. As such, understanding and utilizing these components is crucial for anyone involved in hauling heavy loads.