News

កញ្ញា . 10, 2024 01:08 Back to list

jaw turnbuckle service

Understanding Jaw Turnbuckles and Their Service

Jaw turnbuckles are integral components in various rigging and suspension applications, playing a crucial role in adjusting the tension and length of cables, ropes, or chains. They are commonly used in marine, construction, and industrial settings where secure and adjustable connections are essential.

A jaw turnbuckle consists of two jaws, one on each end, that can be attached to other hardware like hooks, d-rings, or bolts. The central body of the turnbuckle is designed to be twisted, effectively shortening or lengthening the distance between the jaws. This mechanism allows for precise adjustments in tension, making it ideal for applications where consistent, secure fittings are necessary.

Construction and Materials

Jaw turnbuckles are typically made from durable materials such as stainless steel, carbon steel, or alloy steel. Stainless steel is favored for marine applications due to its resistance to corrosion, while carbon steel is preferred for industrial uses where high strength is required. The choice of material depends largely on the intended application and environment, ensuring that the turnbuckle meets safety and longevity standards.

Installation and Adjustment

Installation of jaw turnbuckles requires careful consideration. It's essential to assess the application and ensure that the selected turnbuckle can handle the expected load. Begin by connecting the jaws to the respective fixtures. Once securely attached, turn the central body to adjust the tension. It is important to periodically check the adjustments and ensure that they remain secure over time. Proper installation is key to maintaining safety and functionality.

jaw turnbuckle service

Maintenance and Service

Regular maintenance is crucial to prolonging the life of jaw turnbuckles. Inspect them periodically for signs of wear, corrosion, or deformation. If any issues are detected, replace the turnbuckle immediately to prevent accidents. It’s also advisable to lubricate the threads of the turnbuckle to facilitate smooth adjustments and minimize wear.

Cleaning is another essential aspect of maintenance. Depending on the environment where the turnbuckle is used, dirt and debris can accumulate and hinder its performance. Cleaning the turnbuckle with appropriate solvents can help maintain its functionality and aesthetic appearances.

Safety Considerations

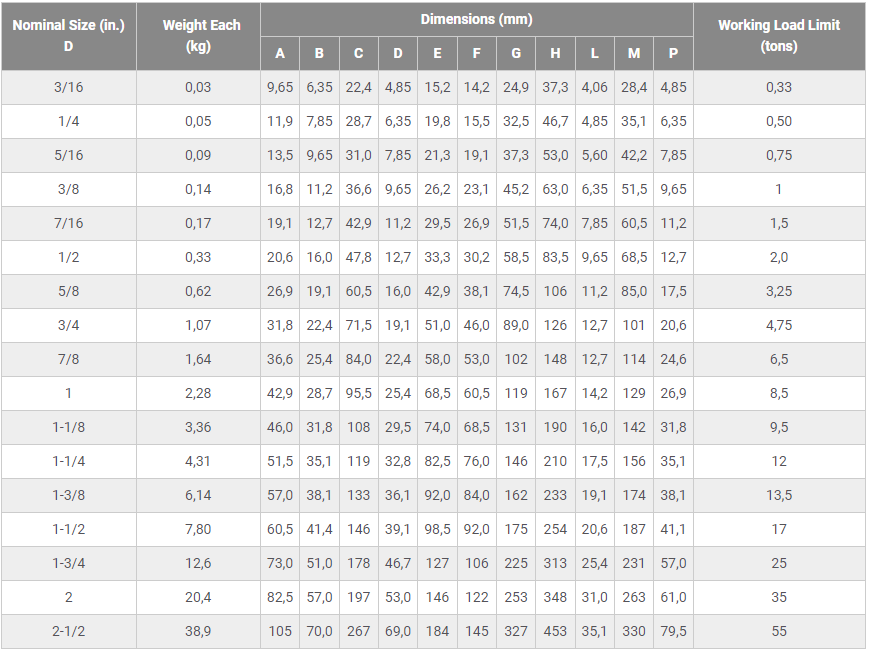

Safety should always be a priority when working with jaw turnbuckles. Ensure that they are rated for the specific load requirements of the task. Overloading or using a turnbuckle beyond its capacity can result in catastrophic failure. Moreover, ensure everything is securely fastened and verify setups routinely, especially in applications subject to dynamic loads or environmental changes.

Conclusion

In summary, jaw turnbuckles are vital components in any rigging system, allowing for the adjustment of tension with ease and precision. Understanding their construction, proper installation, and maintenance can enhance their lifespan and ensure safe operations. With the right care, jaw turnbuckles can provide reliable service in various demanding environments, making them indispensable in both industrial and recreational applications. Regular checks and maintenance practices are essential for keeping these components functioning effectively, ultimately providing peace of mind and safety in every project.