News

វិច្ឆិកា . 14, 2024 16:23 Back to list

custom u eyebolt manufacturer

Custom U Eyebolt Manufacturer Meeting Your Unique Needs

In today’s industrial landscape, where specificity and precision are paramount, the demand for custom solutions has never been higher. One such solution that has gained significant traction is the custom U eyebolt. As a vital component in various applications, from construction to marine operations, the originality and durability of these hardware items are crucial. A custom U eyebolt manufacturer can provide tailored solutions that not only meet industry standards but also cater to the unique requirements of diverse projects.

Understanding U Eyebolts

Before diving into the advantages of custom U eyebolts, it is essential to understand what they are. An eyebolt is a type of fastener that has a ring-shaped head, designed to secure or lift an object. The ‘U’ shape characterizes U eyebolts, which distinguishes them from traditional eyebolts. This unique design allows for a higher level of versatility, making them suitable for a wide range of applications, including pulling, lifting, and fastening.

The Importance of Custom Manufacturing

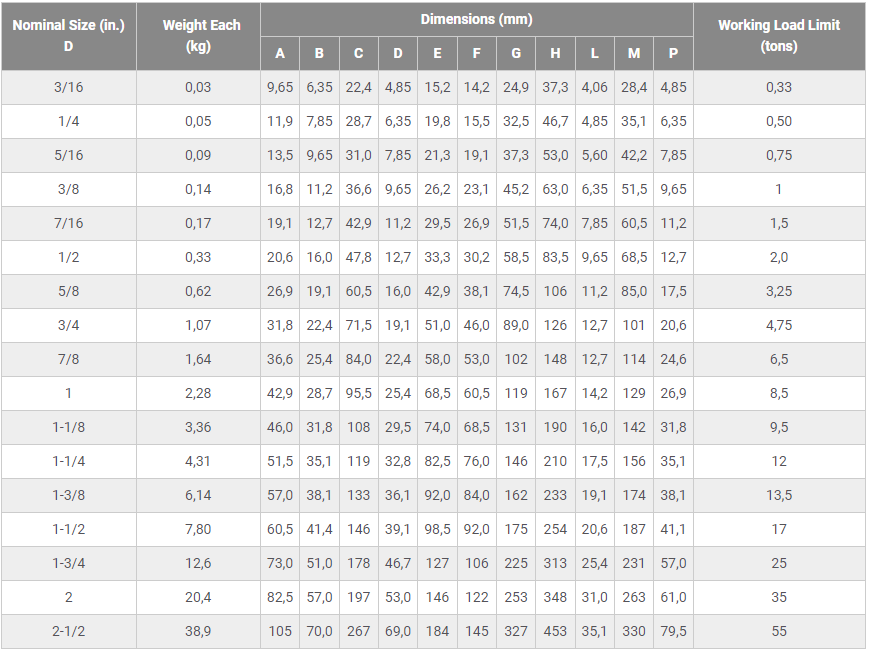

1. Tailored Specifications One of the primary advantages of opting for custom U eyebolts is the ability to specify the dimensions, materials, and finish to meet unique project requirements. A standard product may not always fit the particular needs of a job, which can lead to inefficiencies and safety concerns. Custom manufacturers work closely with clients to develop specifications that align perfectly with their applications.

2. Material Selection Different applications demand different material properties. For example, marine environments often require stainless steel to resist corrosion, while construction projects may need stronger, more robust materials. Custom U eyebolt manufacturers provide a plethora of material options, including steel, stainless steel, and high-strength alloys, ensuring that the right choice is made for the job.

3. Load Capacities Each project comes with its own set of load requirements. A custom manufacturer can engineer U eyebolts that accommodate specific load capacities, ensuring safety and functionality. Whether required for lifting heavy machinery or securing loads in transit, custom solutions can handle the demands effectively.

4. Compliance and Standards Various industries have regulatory standards that components must meet. Custom U eyebolt manufacturers are well-versed in these requirements and can produce eyebolts that comply with industry regulations. This not only enhances safety but also helps avoid legal complications down the line.

custom u eyebolt manufacturer

The Manufacturing Process

The process of creating custom U eyebolts typically involves several steps

- Initial Consultation Clients discuss their needs and specifications with the manufacturer. This step is crucial for establishing a clear understanding of what is required. - Design Engineering The manufacturer will then draft design schematics and technical drawings based on the provided specifications. Advanced software tools may be used to simulate performance under various conditions.

- Material Procurement Once the designs are approved, the manufacturer sources the appropriate materials, ensuring they meet the desired quality standards.

- Fabrication This phase involves machining and shaping the materials into the specified design. Modern manufacturing techniques, such as CNC machining, are employed for precision and efficiency.

- Testing and Quality Control Before the final product is delivered, it undergoes rigorous testing to ensure it meets all performance standards and safety regulations. Quality control checks are essential to validate the integrity of the products.

- Delivery and Support After completing the testing phase, custom U eyebolts are packaged and delivered to the customer. Many manufacturers also provide post-delivery support, ensuring that customers can optimally utilize the eyebolts.

Conclusion

In a world where customization is increasingly becoming a standard expectation, custom U eyebolt manufacturers play a crucial role in delivering specialized solutions. The advantages of tailored specifications, material selection, compliance with industry standards, and the assurance of product quality are just a few reasons why businesses in various sectors choose to work with custom manufacturers. Whether you’re in construction, shipping, or any other industry requiring robust lifting solutions, investing in custom U eyebolts ensures that you get precisely what you need for safe and effective operations. As industries continue to evolve, the role of custom manufacturers will only become more significant, providing the innovation and reliability that modern applications demand.