News

វិច្ឆិកា . 13, 2024 22:04 Back to list

3/8 heim joint turnbuckle factory

The Significance of 3/8% Heims Joint Turnbuckles in Manufacturing

In the realm of mechanical engineering and construction, specific components play a pivotal role in ensuring the integrity and reliability of structures and equipment. Among these components, the 3/8% heim joint turnbuckle stands out due to its unique design and versatile applications. Understanding its functionality and importance can benefit manufacturers, engineers, and builders alike.

What is a Heim Joint Turnbuckle?

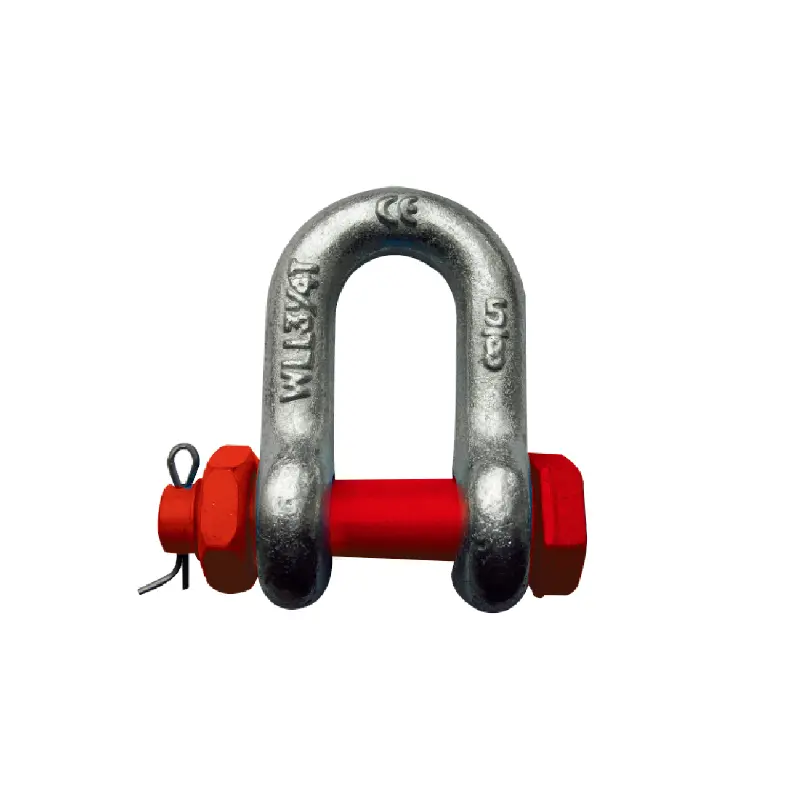

A heim joint turnbuckle is a mechanical device designed to adjust the tension or length of various assemblies. The term heim joint refers to a spherical bearing that allows for a range of motion while maintaining strength and stability. The turnbuckle aspect provides a means for easy adjustment, making it an invaluable tool in construction and mechanical systems. The 3/8% designation typically refers to the diameter of the component, which is essential for ensuring compatibility with various fittings and applications.

Applications of 3/8% Heim Joint Turnbuckles

These turnbuckles are widely used in several industries, including construction, automotive, and aerospace. In construction, they can be found in tensioning applications such as cable systems for buildings, bridges, and various structural assemblies. Their ability to adjust tension accurately ensures that structure remains stable under varying loads and conditions.

In the automotive industry, 3/8% heim joint turnbuckles contribute to the assembly and adjustment of suspension systems. They allow for precise tuning of suspension geometry, which can significantly improve traction and handling. Similarly, in aerospace applications, these turnbuckles are utilized in various control surfaces and linkages, ensuring that mechanical systems operate smoothly and reliably.

3/8 heim joint turnbuckle factory

Advantages of Using 3/8% Heim Joint Turnbuckles

One of the primary advantages of using 3/8% heim joint turnbuckles is their robustness. Constructed from high-quality materials, they withstand harsh environments and heavy loads, which is crucial for maintaining safety and structural integrity. Additionally, their adjustable nature allows for easy fine-tuning during installation and maintenance, saving time and reducing costs.

Another significant advantage is their ease of installation. These components typically come with standard threaded ends that facilitate quick attachment to compatible fittings. This feature is particularly beneficial in high-paced manufacturing environments where efficiency is key.

Quality Manufacturing Practices

The success of a heim joint turnbuckle hinges on the quality of its manufacturing. Factories specializing in these components should adhere to stringent quality control protocols to ensure that each turnbuckle meets industry standards. This involves rigorous testing for strength, durability, and precision. Manufacturers must also consider innovations in materials and design to enhance performance further.

Conclusion

The 3/8% heim joint turnbuckle is an essential component in various industries, providing critical functionality in tensioning systems. Its durable design, ease of installation, and versatility make it a preferred choice among engineers and manufacturers. As industries continue to evolve, the demand for reliable and adjustable components like the heim joint turnbuckle is likely to grow, reinforcing its importance in modern manufacturing and construction practices.