News

Қар . 17, 2024 03:45 Back to list

odm wire rope clips

Understanding ODM Wire Rope Clips An Essential Component in Rigging and Lifting

Wire rope clips play a crucial role in various industries, particularly in lifting, rigging, and construction applications. One particularly prominent type is the ODM wire rope clip. ODM, which stands for Original Design Manufacturer, refers to products that are manufactured by one company for another under the latter’s brand name. When it comes to wire rope clips, ODM manufacturers provide high-quality components designed to meet strict safety standards and performance requirements.

What Are Wire Rope Clips?

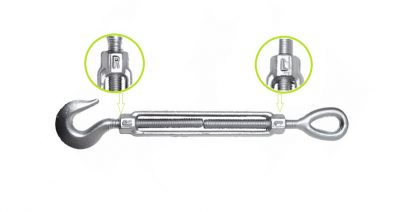

Wire rope clips are devices used to secure the loose end of a wire rope to form a loop, effectively making it a fixture where attachments can be made. These clips typically consist of several parts, including the body, the saddle, and the nuts. Their primary function is to hold the wire rope ends together tightly, preventing slippage and ensuring that the load remains secure throughout operations.

Importance of ODM Wire Rope Clips

In applications where safety is paramount, the use of ODM wire rope clips is critical. Given that these clips are often exposed to harsh environments and considerable loads, their design and manufacturing must adhere to stringent quality controls. ODM producers are responsible for ensuring that their products meet industry regulations and safety standards, providing peace of mind for users.

One significant advantage of ODM clips is their ability to maintain consistency in quality and performance. Manufacturers invest in research and development to create clips that can withstand extreme conditions, such as corrosion and wear, ensuring they last longer than inferior alternatives. High-quality ODM wire rope clips guarantee minimal maintenance needs and enhanced safety during heavy lifting tasks.

Key Features of ODM Wire Rope Clips

1. Material Quality ODM wire rope clips are typically made from high-grade materials such as steel or stainless steel. This selection enhances their strength, durability, and resistance to environmental factors like rust and corrosion. The choice of material plays a fundamental role in the overall longevity of the clips.

2. Design and Engineering OEM manufacturers often collaborate with engineers to develop ergonomically designed clips. The design focuses on uniform load distribution, minimizing the risk of failure under pressure. A well-engineered clip ensures that the wire rope is cradled correctly, providing stability during use.

3. Safety Standards Compliance ODM clips are produced to meet various international safety standards, such as those established by the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA). Compliance with these standards ensures that users can trust the reliability of the clips for various applications.

odm wire rope clips

4. Versatility ODM wire rope clips come in various sizes and configurations, making them suitable for multiple applications, including shipping, construction, and mining. Their versatility allows them to be used in diverse environments, from marine settings to industrial warehouses.

5. Cost-Effectiveness While the initial purchasing cost might be higher than lower-quality alternatives, investing in ODM wire rope clips can be more cost-effective in the long run. Their durability reduces the frequency of replacements, thereby lowering overall operational costs.

How to Properly Install Wire Rope Clips

To ensure the effectiveness of ODM wire rope clips, proper installation is critical

. Here are key steps to follow1. Preparation Cut the wire rope to the desired length and ensure that the ends are clean and free from fraying.

2. Positioning the Clip Place the clip over the wire rope, ensuring that the saddle is in contact with the live end of the rope, while the U-bolt goes around the dead end.

3. Tightening Use a wrench to tighten the nuts on the U-bolt. It is important to apply torque evenly to prevent distortion of the clip and wire rope.

4. Testing After installation, conduct a load test to ensure the clip holds securely under expected loads.

5. Regular Inspection Routinely inspect the wire rope clips for signs of wear, corrosion, or other damage to ensure ongoing safety and performance.

Conclusion

ODM wire rope clips are essential components in various lifting and rigging applications, providing safety and reliability across different industries. Their high-quality design, adherence to safety regulations, and versatility make them a preferred choice for businesses prioritizing both performance and durability. By understanding their features and installation processes, users can maximize the benefits of these indispensable tools. Whether you are in construction, maritime operations, or any field requiring lifting, quality ODM wire rope clips are worth the investment for their long-lasting service and safety assurance.