News

10月 . 20, 2024 20:55 Back to list

China Manufacturers of Beam Clamps for Lifting Applications and Heavy Duty Uses

China Beam Clamp for Lifting A Comprehensive Overview

In the realm of construction and industrial applications, the need for secure and reliable lifting equipment is paramount. Among such equipment, beam clamps hold a significant place, especially in industries that require heavy lifting and precise maneuvering. In China, the production of beam clamps has seen substantial growth, reflecting advancements in technology and manufacturing processes. This article delves into the types, applications, advantages, and considerations surrounding beam clamps produced in China.

Understanding Beam Clamps

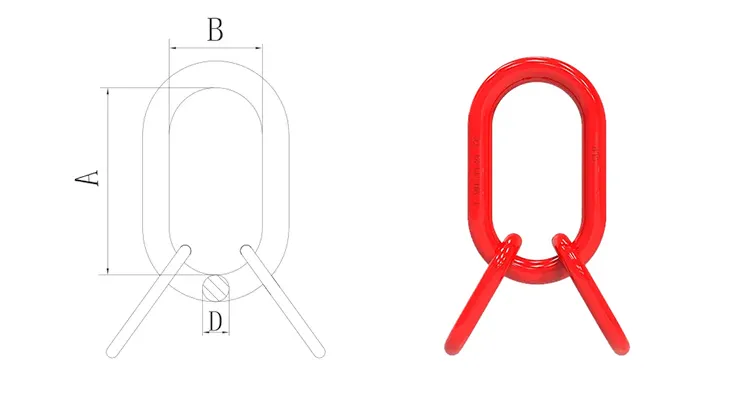

A beam clamp is a device used to create a secure attachment point for lifting and hoisting systems. Typically made from robust materials like steel, these clamps are designed to attach to existing beams or structures without the need for any costly modifications or alterations. This feature is crucial in a variety of settings, from warehouses to construction sites, where flexible lifting solutions are necessary to cater to diverse needs.

Types of Beam Clamps

Various types of beam clamps are manufactured by Chinese factories, each serving different applications. Some common types include

1. Fixed Beam Clamps These clamps provide a permanent solution for attaching lifting points to a beam. They are rigid and are designed for long-term use.

2. Adjustable Beam Clamps These clamps are versatile and can be adjusted to fit different beam sizes and shapes. Their flexibility makes them suitable for temporary installations.

3. Swivel Beam Clamps Designed to allow rotary movement, these clamps enable better maneuverability when lifting loads, facilitating a smoother operation.

4. Vertical and Horizontal Clamps Depending on the lifting orientation required, these clamps are specialized to effectively secure loads in either vertical or horizontal positions.

Applications of Beam Clamps in Various Industries

The utility of beam clamps extends across multiple sectors. In construction, they are essential for lifting steel beams, trusses, and other heavy materials. In manufacturing, beam clamps can assist in moving heavy machinery and components during the assembly process. Additionally, they are frequently used in warehouses for the storage and retrieval of goods, where lifts and cranes play a pivotal role.

Moreover, beam clamps are also instrumental in maintenance and repair operations. For instance, they can be employed to lift equipment in power plants, factories, and other industrial settings, providing easy access for repairs without compromising safety.

Advantages of Using Beam Clamps

china beam clamp for lifting factories

Beam clamps offer several advantages that contribute to their popularity in lifting applications

1. Ease of Use Beam clamps are straightforward to install and do not require complex tools or extensive training, making them accessible for various users.

2. Cost-Effectiveness By eliminating the need for significant structural modifications, beam clamps represent a cost-effective solution for lifting needs.

3. Versatility Their adaptability to different beam sizes and load types enable them to serve diverse lifting tasks, enhancing their value across industries.

4. Safety Features Many modern beam clamps are designed with safety features such as locking mechanisms to prevent accidental release during lifting, ensuring a secure operation.

Considerations When Choosing Beam Clamps

When selecting a beam clamp, several factors should be considered to ensure safe and efficient usage

- Load Capacity It is critical to choose a beam clamp that can safely handle the maximum load expected during operation. Manufacturers typically provide load ratings that should not be exceeded.

- Beam Size Compatibility Ensure that the beam clamp is compatible with the specific dimensions of the beam it will be attached to.

- Material Quality Opt for clamps made from high-quality materials, as this directly affects the durability and performance of the clamp.

- Environmental Conditions Consider the environment in which the beam clamps will be used, as certain materials may be more suited to harsh conditions than others.

Conclusion

As industries continue to evolve, the demand for efficient and reliable lifting solutions like beam clamps will undoubtedly remain strong. Chinese manufacturers are at the forefront of this market, producing a variety of robust and reliable beam clamps that cater to a global audience. By understanding the different types, their applications, and the considerations involved in their use, businesses can enhance their operational efficiency, worker safety, and project success. With the right beam clamp, the challenges of lifting heavy loads can be managed with ease and confidence, paving the way for a more productive work environment.