News

Nov . 04, 2024 10:23 Back to list

High-Quality Winch Shackles from Leading Manufacturers for Your Heavy-Duty Needs

The Essential Role of Winch Shackles in Industrial Applications

In the world of heavy lifting and towing, winch shackles play a crucial role in ensuring safety and efficiency. As a key component in various applications ranging from construction sites to maritime operations, these durable fittings must meet rigorous standards set by manufacturers. Understanding the importance of winch shackles and the qualities that an excellent manufacturer should possess can greatly influence operational success and safety.

Winch shackles are primarily used to connect various components in lifting systems, often bridging the gap between the winch line and the load being lifted. Made from high-strength materials such as forged steel or aluminum, they are designed to withstand significant loads while maintaining their integrity under stress. This quality is vital since any failure in a shackle can lead to catastrophic results, including injuries and equipment damage.

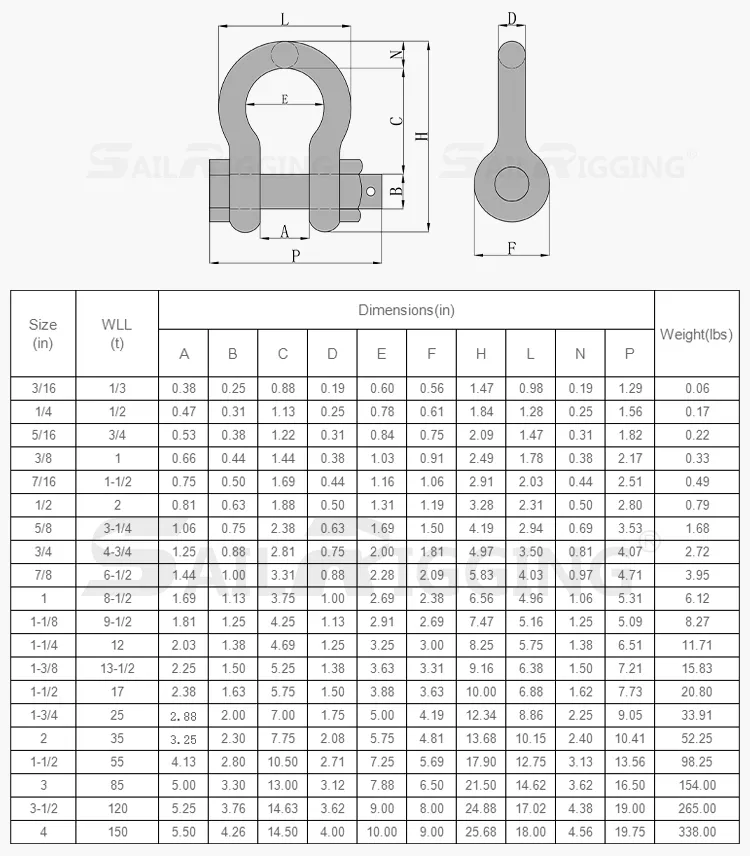

When searching for a winch shackles manufacturer, the first aspect to consider is the material quality. Reputable manufacturers usually provide shackles that have been tested and certified to meet international safety standards. This ensures that the shackles can handle the expected loads over time without risk of failure. Additionally, manufacturers should offer a range of shackles that cater to different applications and weight capacities, allowing clients to choose specific products tailored to their needs.

Another critical factor is the manufacturing process itself. A reliable winch shackles manufacturer will employ cutting-edge technology and machinery to produce their shackles. This includes precision forging, heat treatment, and rigorous quality control procedures that ensure each shackle is free from defects and meets required specifications. Advanced manufacturing processes not only enhance the strength of the shackles but also improve their performance in various environments, whether operating in cold temperatures or corrosive conditions.

winch shackles manufacturer

Moreover, excellent manufacturers offer comprehensive documentation and guidelines for the proper use and maintenance of their shackles. This includes load rating charts, safety instructions, and guidance on connecting shackles with different types of fittings. Educating users about the correct usage of shackles is essential for enforcing safety protocols and reducing the likelihood of accidents on job sites.

Innovation is also a hallmark of a top-tier winch shackles manufacturer. As industries evolve and new technologies emerge, the best manufacturers are always on the lookout for ways to improve their products. This could involve the development of lighter shackles with even greater strength or integrating features that enhance usability, like quick-release mechanisms or corrosion-resistant coatings. Such advancements keep manufacturers competitive while providing customers with cutting-edge solutions for their lifting and towing needs.

Customer service is another integral aspect to consider when selecting a winch shackles manufacturer. A company that prioritizes its clients will establish a clear communication channel, ensuring that inquiries regarding product specifications, availability, and pricing are addressed promptly. Furthermore, they are likely to offer personalized assistance for complex projects, helping customers find the right shackles based on their unique requirements.

In conclusion, winch shackles are indispensable in the heavy-lifting industry. The manufacturer’s reputation can significantly impact the quality and reliability of these crucial components. By focusing on material quality, advanced manufacturing processes, innovation, and robust customer service, the best winch shackles manufacturers not only provide safe and effective lifting solutions but also foster long-term partnerships with their clients. For anyone involved in lifting operations, investing time in selecting the right winch shackles manufacturer can lead to improved safety, operational efficiency, and overall satisfaction in their projects.