News

दिसम्बर . 12, 2024 07:35 Back to list

Shackles and Supplies for Trucking Needs from Trusted Suppliers

Supplier Shackles A Crucial Component for Truck Supply Safety

In the realm of logistics and transportation, safety is paramount. One of the often-overlooked yet critical components that contribute to the safety and efficiency of truck supply chains is the shackle. These seemingly simple devices play a vital role in securing loads, facilitating safe transport, and ensuring that both cargo and trucks are safeguarded against potential mishaps. Understanding suppliers' responsibilities in providing quality shackles is essential for every stakeholder in the supply chain.

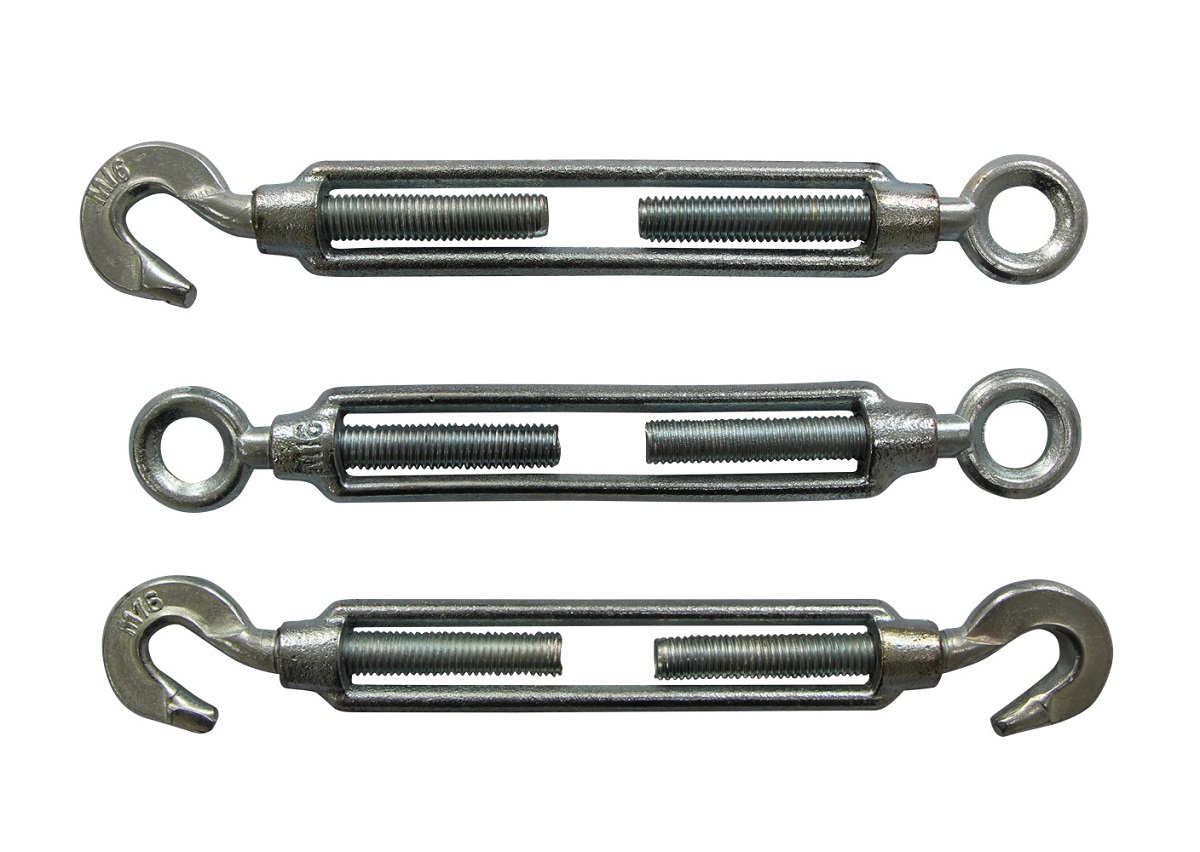

Understanding Shackles

A shackle is a U-shaped piece of metal with a movable pin or bolt. These hardware devices are used to connect different components in lifting or securing applications, making them invaluable in various industries, including construction, shipping, and transportation. In the context of truck supply, shackles are commonly used to secure cargo and equipment to prevent shifting or falling during transit.

The Role of Suppliers in Shackle Quality

The supply of shackles is not just about quantity; it is fundamentally about quality and compliance with safety standards. Suppliers play a crucial role in ensuring that the shackles they provide meet industry regulations and are suitable for their intended use. High-quality shackles are manufactured from durable materials and undergo rigorous testing to ensure their strength and reliability.

When selecting a supplier, it is essential for logistics companies to consider several factors the supplier's reputation, product certifications, and adherence to safety standards. Established suppliers often provide shackles that comply with international standards, such as those set by the American Society for Testing and Materials (ASTM) and the National Association of State Procurement Officials (NASPO). These certifications ensure that products are reliable and safe for use in various applications.

Types of Shackles

There are several types of shackles, each designed for specific applications. The most common types include

1. Bow Shackles These are widely used for lifting and hoisting, thanks to their versatility and strength. They have a large opening, allowing them to connect to various rigging equipment.

supplier shackles truck supply

2. D-Shackles These are used for more secure connections and are excellent for applications with a higher risk of lateral loads. The D shape allows for greater load distribution.

3. Anchor Shackles Often used in marine applications, anchor shackles are designed to withstand harsh environments, providing durability and security in challenging conditions.

Understanding the differences among these shackles is vital for selecting the right type for specific cargo and operational requirements.

Importance of Regular Inspections and Maintenance

Once shackles are in use, their maintenance becomes critical for ongoing safety. Regular inspections should be conducted to check for any signs of wear, deformation, or damage. A damaged shackle can lead to catastrophic failures, endangering lives and causing significant financial losses. Suppliers often provide guidelines on how to maintain and inspect shackles, and logistics companies should ensure that these protocols are followed diligently.

Conclusion A Partnership for Safety

In conclusion, the role of suppliers in the shackle market is indispensable. They are not merely vendors but critical partners in ensuring the safety and efficiency of truck supply operations. By selecting the right suppliers and adhering to proper maintenance protocols, logistics companies can significantly reduce the risks associated with cargo transport.

Moreover, as industries evolve and regulations tighten around safety practices, the demand for high-quality shackles will only grow. Emphasizing supplier quality, type appropriateness, and maintenance diligence will not only enhance safety but also elevate operational efficiency within the supply chain.

For companies involved in logistics and supply chain management, understanding the importance of shackles and forging strong partnerships with reliable suppliers can make all the difference in achieving a secure and efficient transport system. Thus, investing time and resources in selecting top-notch shackles and suppliers is not just a good practice; it is a fundamental necessity for success in the industry.