News

दिसम्बर . 04, 2024 18:19 Back to list

custom rigging accessories factory

Custom Rigging Accessories Factory Enhancing Your Lifting Solutions

In today’s industrial landscape, where safety and efficiency are paramount, the demand for high-quality rigging accessories has never been higher. Custom rigging accessories factories have emerged as key players in this sector, providing tailored solutions that cater to the specific needs of various industries, including construction, manufacturing, and maritime operations. This article explores the significance of custom rigging accessories, the manufacturing process, and the advantages of sourcing from specialized factories.

Understanding Rigging Accessories

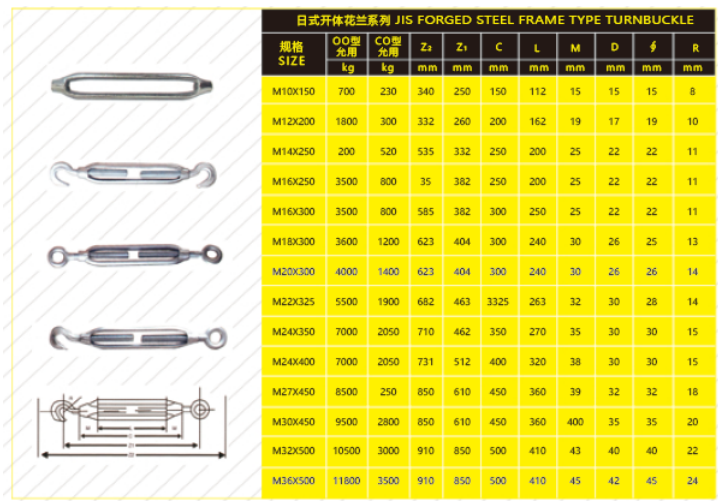

Rigging accessories are integral components used in lifting operations. They include hardware such as shackles, hoists, slings, and high-tensile cables that facilitate the safe and efficient movement of heavy loads. The versatility of these accessories enables their application in diverse environments, from lifting heavy machinery to securing cargo on ships. However, the effectiveness of rigging equipment relies heavily on its design and specification, which is where custom solutions shine.

The Role of Customization

Every lifting scenario presents unique challenges, necessitating tailor-made solutions that off-the-shelf products may not effectively address. A custom rigging accessories factory specializes in creating products designed for specific applications, considering factors such as load capacity, environmental conditions, and operational requirements. This level of customization ensures that the equipment meets compliance standards and enhances overall safety.

Custom rigging solutions can include the fabrication of high-strength slings that are specially woven to endure extreme wear conditions, or bespoke lifting frames designed to distribute weight evenly across multiple points. These personalized aspects not only improve the efficiency of lifting operations but also minimize the risk of equipment failure and accidents.

The Manufacturing Process

A reputable custom rigging accessories factory follows a comprehensive manufacturing process that maintains high-quality standards. Typically, this involves several key stages

1. Consultation and Design Engaging with customers to understand their specific needs and operational contexts is the first step. Engineers and designers collaborate to create detailed specifications, incorporating materials that align with performance requirements.

2. Material Selection The choice of materials is crucial for ensuring that rigging accessories can withstand the stresses they will encounter. Options may include high-strength steel, synthetic fibers, and specialized coatings to resist corrosion.

custom rigging accessories factory

3. Fabrication Using advanced machinery, the factory fabricates the rigging components according to the approved design. This stage often incorporates precision techniques like welding, cutting, and molding to achieve the desired specifications.

4. Quality Control Rigorous testing is conducted throughout the manufacturing process. This includes load tests, strain measurements, and inspections to ensure that every product meets the required safety standards.

5. Final Assembly Once all components have been independently tested, they are assembled. The final pieces are again scrutinized for quality assurance before being packaged for delivery.

The Advantages of Custom Solutions

Opting for a custom rigging accessories factory offers numerous benefits

- Safety Customized products designed for specific loads and conditions significantly enhance safety in lifting operations. Tailored solutions also promote compliance with industry regulations and standards.

- Efficiency Customized rigging accessories can optimize the logistics of lifting and securing loads, leading to reduced downtime and improved productivity.

- Longevity High-quality materials and precise designs contribute to the durability of custom solutions, making them a worthwhile investment in the long run.

- Expertise and Support Working with a specialized factory provides access to expert advice and support, ensuring that customers receive guidance on usage, maintenance, and future upgrades.

Conclusion

In the rapidly evolving industrial environment, utilizing custom rigging accessories is essential for enhancing safety and operational efficiency. The role of custom rigging accessories factories in this regard cannot be understated. By offering tailored solutions that meet the specific needs of various industries, these factories help ensure that lifting operations are conducted smoothly and safely. As industries continue to embrace bespoke solutions, the importance of collaboration with custom rigging accessory manufacturers will only increase, paving the way for safer and more efficient work environments. Whether it's for lifting in construction, handling cargo in shipping, or any other application, investing in custom rigging accessories is not just a choice—it's a necessity for any operation that values safety and performance.