News

דצמ . 04, 2024 05:55 Back to list

Lifting and Rigging Solutions for Enhanced Safety and Efficiency in Industrial Applications

Lifting and Rigging in Modern Factories A Comprehensive Overview

In today’s fast-paced industrial landscape, lifting and rigging play an essential role in ensuring the safe and efficient movement of heavy materials and equipment within factories. These operations are critical not only for maintaining productivity but also for ensuring the safety of all personnel involved. This article will explore the significance of lifting and rigging in factories, the equipment involved, safety considerations, and best practices that can help optimize these operations.

The Importance of Lifting and Rigging

Factories often deal with large machinery, components, and raw materials that require careful handling. Effective lifting and rigging solutions allow businesses to move heavy items with precision, reducing the risk of damage to goods and ensuring that operations continue to flow smoothly. Furthermore, these practices contribute to the overall safety of the workplace environment, minimizing the risk of accidents and injuries.

Types of Lifting Equipment

1. Cranes One of the most common types of lifting equipment in factories. Cranes come in various forms, such as overhead cranes, gantry cranes, and jib cranes, each suited to specific tasks. They are versatile and can lift heavy items off the ground with high accuracy.

2. Hoists These devices are used to lift and lower loads and can be powered electrically, pneumatically, or manually. Hoists are often attached to cranes, making them integral components of a lifting system.

3. Forklifts While not traditional lifting equipment, forklifts are vital in warehouses and factories for moving materials around. Their ability to stack and transport pallets of goods makes them indispensable for efficient operations.

4. Slings Slings are used to secure loads during lifting operations. They can be made from various materials, including nylon, polyester, and wire rope, and they come in a variety of configurations for different applications.

Rigging Fundamentals

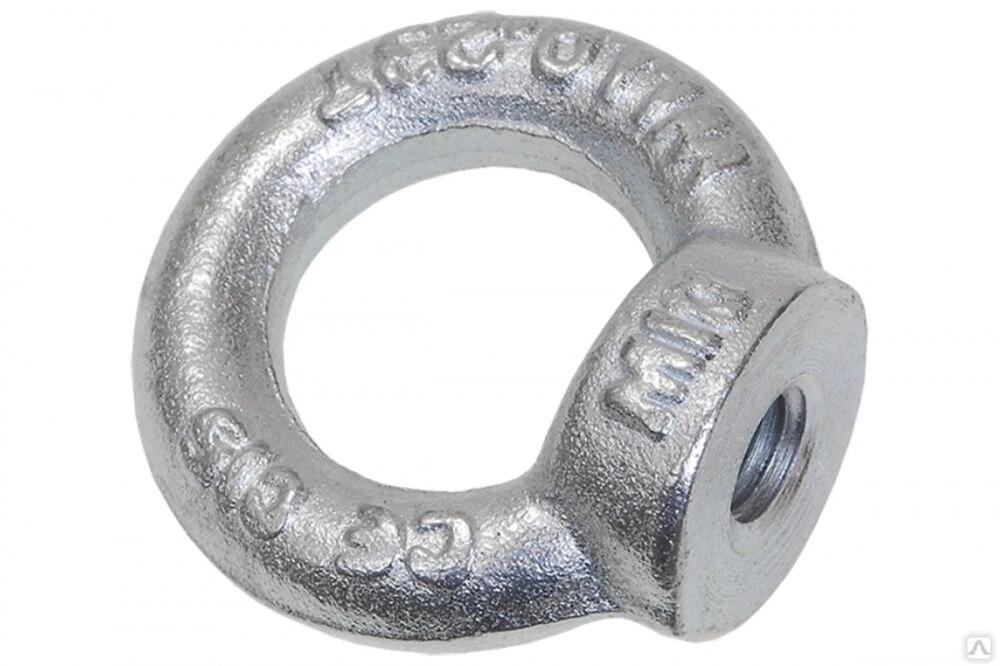

Rigging is the process of setting up the equipment used for lifting. It involves the selection and application of various lifting devices, such as shackles, hooks, and slings, to ensure that the load is balanced and secure. Proper rigging is crucial for preventing accidents and ensuring the load is lifted safely and efficiently.

Safety Considerations

Safety is paramount in lifting and rigging operations. Some key safety practices include

lifting and rigging factory

1. Training Ensuring that all operators and riggers are properly trained in the safe use of equipment is crucial. Certification programs can help equip workers with the necessary skills and knowledge to handle lifting operations safely.

2. Regular Inspections Equipment should be regularly inspected for wear and tear. This includes checking hooks, chains, and slings for any signs of damage that could compromise safety.

3. Load Limits Operators must always adhere to the manufacturer's specified load limits for cranes and slings. Overloading equipment can lead to failures and accidents.

4. Planning Before undertaking a lifting operation, careful planning is essential. This includes assessing the load, the environment, and the capabilities of the equipment to be used.

5. Communication Clear communication among team members is vital during lifting operations. Establishing hand signals or using radio communication can significantly reduce the risk of misunderstandings that could lead to accidents.

Best Practices for Optimization

To maximize efficiency in lifting and rigging operations, consider implementing the following best practices

1. Adopt Technology Utilize technology like load monitoring systems to keep track of weights and ensure that loads are within safe limits during lifting.

2. Inventory Management Keeping an up-to-date inventory of all lifting and rigging equipment helps ensure that all necessary gear is available and in good condition when needed.

3. Continuous Improvement Regularly review and evaluate lifting and rigging operations to identify potential areas for improvement. This can help reduce costs and increase safety and efficiency.

Conclusion

Lifting and rigging are integral parts of modern factory operations. By understanding the importance of these practices, investing in the right equipment, adhering to safety protocols, and continuously striving for improvement, factories can enhance productivity while ensuring a safe working environment. With the proper approach, lifting and rigging can be executed seamlessly, paving the way for operational success in any industrial setting.