News

דצמ . 12, 2024 01:50 Back to list

c beam clamp products

Exploring C-Beam Clamp Products Enhancing Precision in Structural Engineering

In the realm of structural engineering and manufacturing, the importance of precision and efficiency cannot be overstated. Among the myriad of tools and components that contribute to successful projects, C-beam clamps stand out as essential components that ensure stability and reliability in various applications. This article delves into the specifics of C-beam clamp products, exploring their design, applications, and benefits in enhancing project efficiency.

What are C-Beam Clamps?

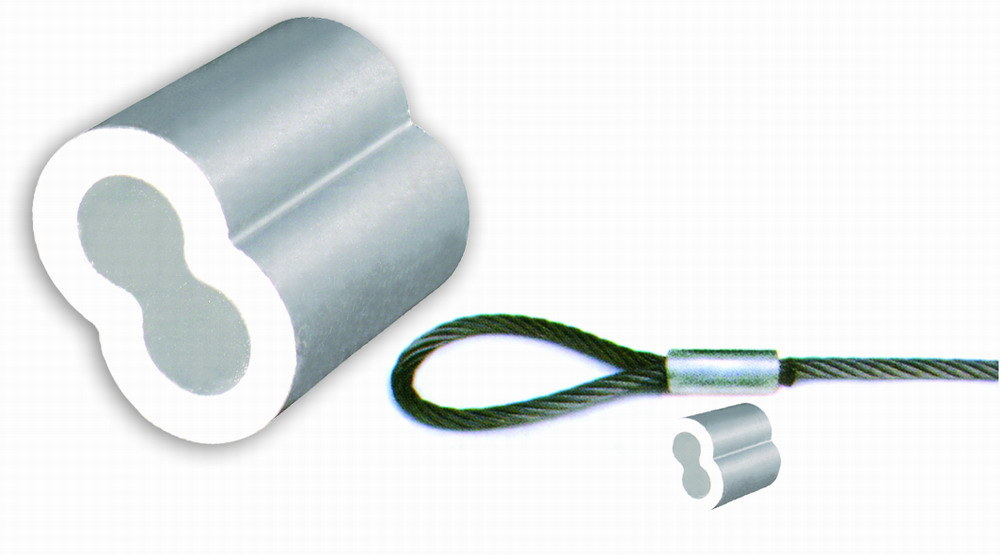

C-beam clamps are specialized connectors used for securing parts of a framework or structure that is based on C-beams, a type of extruded aluminum I-beam. The unique shape of C-beams offers a sturdy foundation while also enabling a lightweight construction. C-beam clamps come in various sizes and designs, allowing engineers and builders to choose the most suitable options based on their specific project needs. The primary function of these clamps is to provide a robust joining solution that ensures lasting stability throughout the lifecycle of the structure.

Design and Features

The design of C-beam clamps is critical to their functionality. Most clamps are made from high-quality aluminum alloy or steel, providing the necessary strength while minimizing weight. The clamps often feature adjustable components, allowing for precise positioning during assembly. Some innovative designs include integrated locking mechanisms that enhance security and prevent slippage under load. Additionally, many clamps are designed to accommodate standard nuts and bolts, making installation straightforward and hassle-free.

One of the defining characteristics of C-beam clamps is their versatility. They can be utilized in various configurations, including horizontal, vertical, and angled orientations. This flexibility allows engineers to develop complex structures without compromising stability. Furthermore, the modular nature of the C-beam system enables easy reconfiguration, making repairs or upgrades simpler than traditional construction methods.

Applications of C-Beam Clamps

C-beam clamps find their place in a multitude of applications across various industries. In robotics and automation, C-beams and clamps are frequently used to construct frames for automated systems, assembly lines, and custom machine components. Their lightweight yet sturdy nature allows for the efficient transportation of goods and components, which is crucial in high-speed production environments.

c beam clamp products

In the realm of woodworking and furniture design, C-beams offer a modern approach to creating sturdy yet aesthetically pleasing structures. Designers often employ C-beam clamps to construct shelving units, workstations, and display cases, ensuring a clean, industrial look without sacrificing stability.

Moreover, C-beam clamps are widely used in the design and construction of custom enclosures for electronics and software systems. The ability to precisely control the dimensions and strength of a frame enhances both performance and safety in sensitive environments.

Benefits of Using C-Beam Clamps

The benefits of utilizing C-beam clamps are manifold. Firstly, they significantly reduce the time required for assembly due to their ease of use and flexibility in configuration. This time-saving can lead to reduced labor costs and shorter project timelines. The modular nature of C-beams allows for quicker modifications and repairs, enhancing long-term efficiency.

Secondly, the stability and security offered by C-beam clamps help in minimizing the risks associated with structural failures. Reliable clamps ensure that all components remain securely connected, providing peace of mind for engineers and builders alike. Additionally, the lightweight properties of C-beams reduce transportation costs and allow for easier handling on-site.

Lastly, the aesthetic versatility of C-beam construction allows designs to be tailored to specific visual requirements, making it a popular choice for contemporary projects. The sleek look of aluminum combined with functional design contributes to modern architectural trends.

Conclusion

In conclusion, C-beam clamp products play a vital role in modern structural engineering, enabling precision, efficiency, and aesthetic appeal in various applications. Their robust design, versatility, and numerous benefits make them indispensable tools in the construction of frames, systems, and structures across diverse industries. By integrating C-beam clamps into projects, professionals can achieve exceptional reliability and visual appeal, ultimately leading to the successful realization of their engineering visions.