News

ડીસેમ્બર . 12, 2024 11:22 Back to list

supplier wire rope clip typest

Understanding the Different Types of Wire Rope Clips

Wire rope clips play a crucial role in a variety of industries, from construction to marine applications. They are essential for securing and forming loops in wire ropes, ensuring safety and functionality in various applications. This article will delve into the different types of wire rope clips, their applications, and key considerations for selection.

What are Wire Rope Clips?

Wire rope clips, also known as wire rope clamps, are devices designed to clamp a wire rope securely, allowing for the creation of a loop at the end of the wire. They typically consist of a U-shaped bolt, a saddle, and two nuts. When tightened, the saddle holds the wire rope in place, creating a secure and strong connection.

Types of Wire Rope Clips

1. Standard Wire Rope Clips - These are the most common type of clips and are made from mild steel or stainless steel for corrosion resistance. They are suitable for general applications where strength and durability are required.

2. Screw Pin Wire Rope Clips - This type features a screw pin instead of a traditional nut. The screw pin allows for quicker assembly and disassembly, which is beneficial in applications that require frequent adjustments or removals.

3. Locking Wire Rope Clips - These clips are designed with an additional locking mechanism to prevent loosening due to vibration or dynamic loads. They are ideal for high-stress applications where movement is expected.

4. Heavy-Duty Wire Rope Clips - Constructed from thicker materials and often with larger dimensions, these clips are designed to support heavier loads. They are commonly used in industries such as construction, mining, and maritime operations.

5. Specialty Wire Rope Clips - Some clips are designed for specific applications and may include features like improved corrosion resistance or added flexibility. These might include clips made from specialized alloys or those designed for use in high-temperature environments.

Applications of Wire Rope Clips

supplier wire rope clip typest

Wire rope clips are used in a multitude of applications

- Construction Used to secure lifting cables and support structures. - Marine Essential for securing lines on ships, docks, and other marine installations. - Warehousing Used for lifting and securing loads in warehouses and distribution centers. - Transportation Employed in the transportation of goods and equipment, ensuring secure loads.

Key Considerations When Choosing Wire Rope Clips

1. Load Capacity Always consider the weight and type of load the clip will be securing. Different clips have varying load ratings, and selecting an insufficient clip can lead to failure.

2. Material Choose the appropriate material depending on the environment. Stainless steel is preferred in corrosive environments, while galvanized steel can be suitable for less severe conditions.

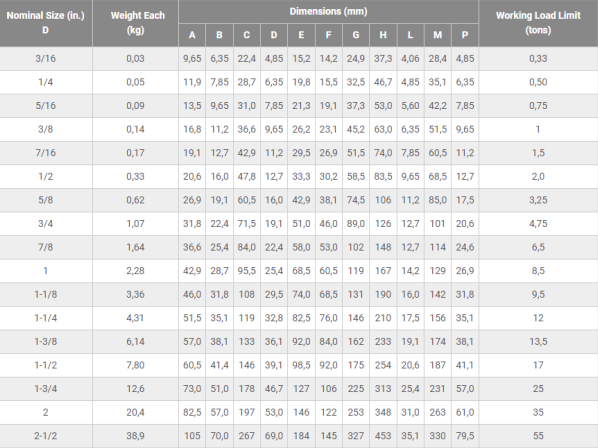

3. Size Compatibility Ensure that the wire rope clip is compatible with the diameter of the wire rope being used. Clips come in various sizes, and using the correct size ensures optimal performance.

4. Installation Proper installation is crucial for the effectiveness of wire rope clips. Follow manufacturer guidelines regarding the number of clips needed and the spacing between them.

5. Maintenance Regular inspection and maintenance of wire rope clips are essential to ensure their reliability and safety. Check for signs of wear, corrosion, or damage.

Conclusion

Wire rope clips may seem simple, but they are vital components in ensuring the safety and efficacy of various cable systems. Understanding the different types of wire rope clips and their applications can help in selecting the right clip for specific needs. Whether in construction, marine, or other industries, using the correct wire rope clip ensures secure connections and enhances safety in operations. Remember to consider load capacity, material, compatibility, installation, and maintenance when choosing wire rope clips to maximize their effectiveness and longevity. By doing so, you can help guarantee the safety and reliability of your wire rope systems.