- +8613831024085

- infohengou@gmail.com

News

સપ્ટેમ્બર . 02, 2024 04:06 Back to list

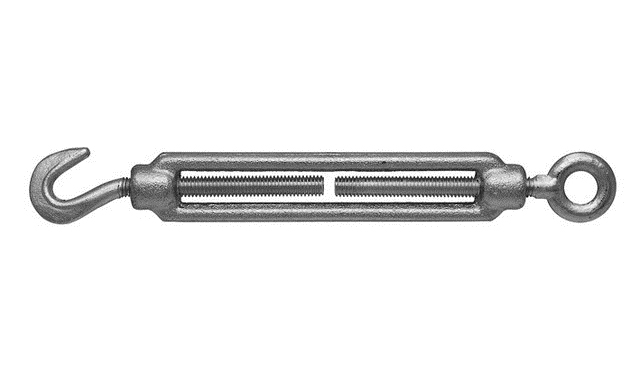

High-Quality Clevis Turnbuckles for Reliable Tension Control

Understanding Clevis Turnbuckle Service

In various industries, from construction to marine applications, the need for strength, stability, and adjustability is paramount. One component that plays a critical role in achieving these qualities is the clevis turnbuckle. This mechanical device is designed to adjust the tension and length of cables, ropes, and rods, making it an essential part of rigging systems.

A clevis turnbuckle consists of two clevises that are attached to a central body which can be twisted to either tighten or loosen the lines it connects. The clevis itself is a U-shaped metal piece with holes for bolts, allowing it to securely attach to various structures. The turnbuckle's design allows for a quick adjustment in tension without needing to disassemble the entire rigging setup, making it especially valuable in dynamic environments where conditions can change rapidly.

Importance of Regular Service

Like any mechanical system, clevis turnbuckles require regular maintenance to ensure optimal performance and safety. Over time, factors such as corrosion, dirt accumulation, or metal fatigue can compromise their functionality. Regular service not only extends the life of the turnbuckle but also enhances the safety of the overall system.

During a service check, it's vital to inspect the clevis turnbuckle for signs of wear, including cracks or distortions in the metal. Inspectors should also ensure that the threads on the turnbuckle are free from damage and that the mechanism operates smoothly. Lubrication is also important; applying the right lubricant to the threaded area can minimize friction and prevent seizing.

Common Issues and Solutions

clevis turnbuckle service

One of the most common issues encountered with clevis turnbuckles is corrosion, particularly in environments exposed to moisture or chemicals. When rust forms, it not only weakens the turnbuckle but can make adjustment difficult. In such cases, a thorough cleaning and application of a protective coating can significantly improve longevity.

Another issue to watch out for is misalignment during installation. If the turnbuckle is not properly aligned with the connecting parts, it can lead to uneven stress, resulting in premature failure. Ensuring that each component is correctly positioned before tightening is crucial in preventing this situation.

Best Practices for Use and Maintenance

To maximize the effectiveness of clevis turnbuckles, adherence to best practices is essential. First, always adhere to the manufacturer's specifications regarding load limits and installation procedures. Exceeding these parameters can lead to catastrophic failures.

Moreover, incorporate regular inspection schedules into your maintenance routine. Documenting these inspections will not only help in maintaining safety standards but will also be beneficial for tracking performance and trends over time.

In conclusion, while clevis turnbuckles may seem like small components, their role in securing and adjusting tension in various applications is vital. Prioritizing regular service and maintenance will not only enhance their performance but also ensure the safety and reliability of the systems they support. By following best practices and addressing common issues proactively, users can enjoy the full benefits offered by clevis turnbuckles in their operational configurations.