News

Set . 09, 2024 18:57 Back to list

eye bolt rigging manufacturers

Eye Bolt Rigging Manufacturers Ensuring Safety and Efficiency in Lifting Operations

In various industrial sectors, lifting heavy equipment or materials is a routine part of operations. Whether in construction, shipping, or manufacturing, safe and reliable lifting mechanisms are paramount. Eye bolts are crucial components in rigging that facilitate these lifting processes. Understanding the importance of quality eye bolt rigging manufacturers can help businesses make informed decisions that enhance both safety and efficiency in their operations.

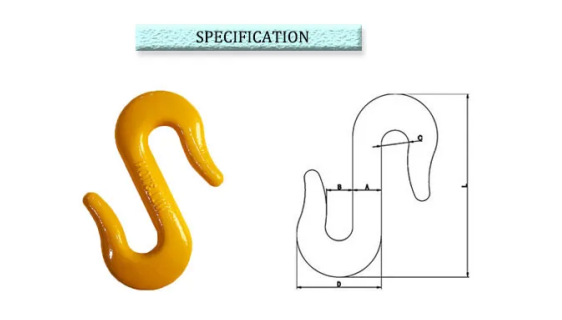

Eye bolts are designed as a type of fastener with a loop on one end. This loop enables the attachment of a hook, chain, or rope for lifting. The primary function of an eye bolt is to provide a secure anchor point that can withstand significant loads, making them essential in a variety of applications from hoisting machinery to securing objects. However, the structural integrity of each eye bolt is highly dependent on the quality of the materials and the manufacturing processes used.

Reputable eye bolt rigging manufacturers prioritize the use of high-grade materials, such as stainless steel or carbon steel, specifically designed for strength and durability. These materials provide resistance against corrosion, wear, and deformation, which is essential in maintaining the safety and reliability of lifting operations. Additionally, top manufacturers adhere to stringent manufacturing standards and safety regulations, such as those set by the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). Compliance with these standards not only reflects a commitment to quality but also ensures that the eye bolts can perform safely under defined load limits.

eye bolt rigging manufacturers

Another critical aspect to consider when selecting eye bolt rigging manufacturers is their ability to provide a variety of eye bolt types and sizes tailored to specific applications. Some manufacturers offer custom solutions to meet unique requirements, providing designs that can accommodate different load capacities and angles of application. This flexibility is essential as it allows businesses to select the right eye bolt for their specific needs, ensuring both effectiveness and safety.

Customer support and technical expertise are also significant factors in choosing the right manufacturer. Reputable manufacturers often have knowledgeable representatives who can assist clients in selecting the proper rigging solutions. They can provide insights into load ratings, installation practices, and maintenance procedures, helping to prevent accidents caused by improper use or installation of eye bolts.

Moreover, as industries increasingly focus on sustainability, many eye bolt rigging manufacturers are incorporating environmentally friendly practices in their production processes. This includes using recycled materials and adopting energy-efficient manufacturing methods. Such efforts not only contribute to a greener planet but also resonate with clients who prioritize sustainability in their supply chains.

In conclusion, the choice of eye bolt rigging manufacturers plays a vital role in ensuring the safety and efficiency of lifting operations across various industries. By prioritizing quality materials, adhering to stringent safety standards, providing a diverse range of products, and offering expert support, leading manufacturers help organizations mitigate risks associated with lifting heavy loads. Investing in reliable eye bolt solutions is not just about meeting operational needs; it’s about fostering a culture of safety and excellence in every lift.