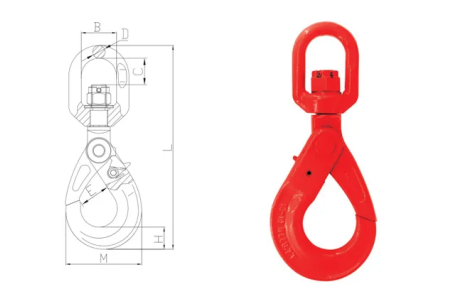

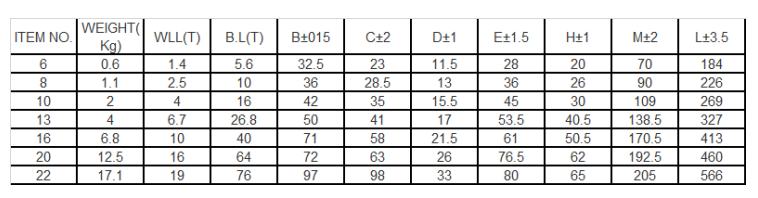

G80 European Swivel Self-locking Hook, imported EuropeanSwivel Self-locking Hook, imported G80 European rotating safety hook (rotating self-locking hook) is forged from high-strength and high toughness special alloy steel, and has undergone heat treatment. Used in conjunction with a grade 80 chain. Conduct validation tests at 2.5 times the working tension. Sample 20000 fatigue tests. Conduct strict sampling and breaking tests on each batch of products. Perform foundation powder inspection. Surface treatment: spray molding. The breaking force is four times the working force

G80 rotary self-locking safety hook is a kind of hook commonly used in hoisting. It can attach objects or ropes alone, and can also be used together with other riggings. Through the cooperation between the hook body, swing arm and self-locking device, it can effectively prevent the lifting cargo from unhooking, improve the bearing capacity of the safety hook, and improve the Factor of safety of the safety hook. The safety self-locking device of the safety hook can be pressed by the thumb, and is easy to use, The spring device is simple and easy to maintain, and the main body of the insurance is mostly located inside the hook body, which is not easily damaged and more safe and reliable. The hook can rotate 360 degrees horizontally and can be used for anti rotation lifting and hoisting on-site.

Do you need to pay attention to any other aspects during use? Let's take a look together now!

Crane safety management staff and machine maintenance staff should number the hooks after they enter the warehouse, and then make sturdy, wear-resistant, and self-locking hanging signs; The label should include the number, performance, and effective time for safety testing; The principle of hanging signs is that they should be hung on the hooks, not hindering operation, and in an area that is not easily worn. If the hooks are very small, such as shackles, you can choose to hang the signs on their corresponding storage racks; During the operation of the hook, maintenance personnel should undergo regular safety inspections, and the effective time for safety inspections is 6 months; After 6 months, the hook should be re inspected by the maintenance staff before it can be put into use.

The above are some aspects that should be paid attention to when using hooks, and everyone should also pay attention to them when using them in daily life!