News

Nov . 26, 2024 08:29 Back to list

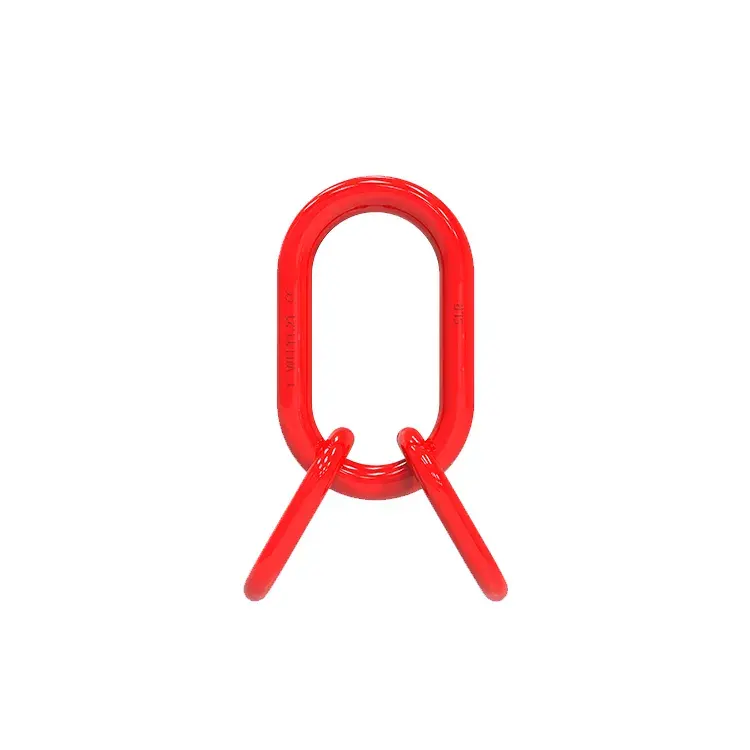

Turnbuckle Jaw Supplier for Reliable and Durable Construction Solutions

Understanding Turnbuckle Jaw Exporters A Comprehensive Overview

In the world of construction, manufacturing, and various engineering applications, turnbuckles play a crucial role in ensuring stability and strength in structures and frameworks. Among the various components that make up a turnbuckle, the jaw is an integral piece that allows for effective tensioning and adjustments. With the rising global demand for reliable turnbuckle components, the role of turnbuckle jaw exporters has become increasingly significant. In this article, we will explore the functions of turnbuckles and their jaws, the factors influencing their exportation, and how businesses can benefit from connecting with reputable exporters in this industry.

What are Turnbuckles?

Turnbuckles are mechanical devices used to adjust tension or length in cables, ropes, or tie rods. They consist of a metal frame with two eye or jaw ends that can be rotated in opposite directions, making it easier to tighten or loosen the connection. Turnbuckles are widely used in construction, rigging, maritime applications, and various industrial settings. The jaw end of a turnbuckle is particularly important as it provides the means to connect the device to other components, such as cables or hooks.

The Function of Turnbuckle Jaws

The jaws of a turnbuckle can either be a hook, eye, or fork type. Each type serves different applications depending on the requirements of the installation. For instance, jaw hooks are often used in situations where quick attachment and detachment are needed, whereas eye jaws provide a more secure connection suited for heavy loads. The ability to adjust the tension with a simple twist makes turnbuckles essential in applications where stability is vital.

The Role of Exporters

Turnbuckle jaw exporters facilitate the global trade of these crucial components. They serve as intermediaries that connect manufacturers with businesses worldwide, ensuring that quality turnbuckle jaws reach various markets efficiently. It is imperative that exporters maintain high standards of quality and compliance with international regulations, as the applications of turnbuckle jaws involve high-stress scenarios where failure could lead to catastrophic consequences.

Factors Affecting Turnbuckle Jaw Exportation

Several factors impact the dynamics of turnbuckle jaw exportation

1. Material Quality The choice of material significantly affects performance. High-quality steel or corrosion-resistant materials are often preferred, as they enhance durability and performance under various conditions.

turnbuckle jaw exporter

3. Regulatory Compliance Exporters must adhere to international safety standards and regulations, which can vary by region. Failure to comply can result in legal issues and financial losses.

4. Technological Advancements Innovations in manufacturing and design can influence the types of turnbuckle jaws exported, as companies seek more efficient and effective solutions.

Connecting with Reputable Exporters

For businesses looking to source turnbuckle jaws, partnering with a reputable exporter can provide numerous advantages. Here are some tips for identifying a reliable exporter

- Research Conduct thorough research to find exporters with a proven track record in providing quality turnbuckle components.

- Certifications Ensure that the exporter possesses the necessary certifications and adherence to quality standards.

- Client Reviews and Testimonials Look for testimonials from previous clients to gauge the exporter’s reliability and customer service.

- Sample Orders Requesting sample orders can help assess product quality before entering into a larger business relationship.

Conclusion

Turnbuckle jaws are essential components that contribute to the stability and safety of various structures and systems. As the demand for these components continues to grow, the role of turnbuckle jaw exporters becomes even more critical. By understanding the functions of turnbuckle jaws, the factors influencing their exportation, and establishing connections with reputable exporters, businesses can ensure they have access to high-quality components that meet their operational needs. Whether it’s for a construction project, an industrial application, or maritime rigging, selecting the right turnbuckle jaws can make all the difference in achieving success and safety in any endeavor.