News

Lis . 22, 2024 02:21 Back to list

turnbuckles supply factory

Understanding Turnbuckle Supply Factories A Comprehensive Overview

The world of mechanical fittings and hardware is extensive and diverse, reflecting a myriad of industrial needs. Among these, turnbuckles hold a significant place, serving essential functions in various applications, from construction to maritime industries. A turnbuckle supply factory specializes in producing these ingenious devices, and understanding their role and manufacturing process can shed light on their importance in the field.

What is a Turnbuckle?

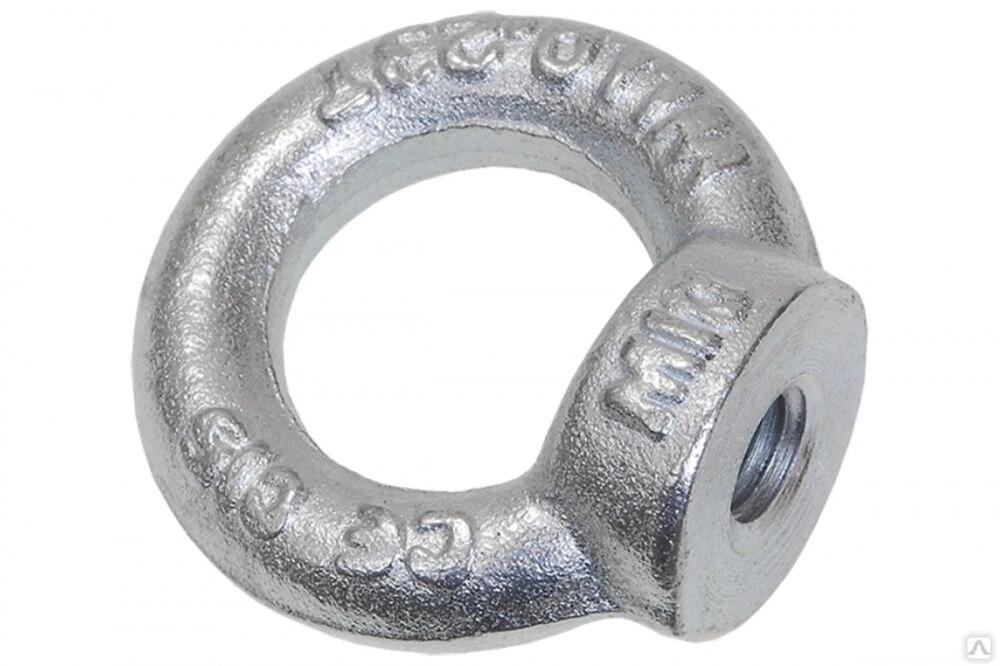

A turnbuckle is a mechanical device used to adjust the tension or length of a cable, rope, or rod. It consists of two threaded eye bolts inserted into a metal frame, allowing for linear adjustment by turning the body of the turnbuckle. The versatility and simplicity of this device make it a favored choice for ensuring structural stability in various settings.

The Role of Turnbuckle Supply Factories

Turnbuckle supply factories are crucial in supplying these devices to meet the demands of various industries. These factories focus on the design, manufacturing, and distribution of turnbuckles, ensuring they meet safety standards and client specifications. The manufacturing process often includes

1. Materials Selection The first step in producing turnbuckles is selecting the right materials. Most turnbuckles are made from steel, stainless steel, or aluminum due to their strength and durability. Factories often choose materials based on the end application, such as corrosion-resistant materials for marine applications or lightweight alloys for aerial rigging.

2. Machining and Forging The raw materials undergo machining or forging to create the required shapes. Precision is critical in this stage to ensure that the threads on the eye bolts are accurately made for proper functionality.

3. Heat Treatment To enhance the strength of the turnbuckles, manufacturers often subject the parts to heat treatment processes. This increases tensile strength and resistance to wear, which is crucial for devices subjected to constant tension.

turnbuckles supply factory

4. Finishing The surface of the turnbuckles may undergo finishing processes such as polishing, coating, or galvanizing, depending on their intended use. These treatments can significantly improve corrosion resistance, contributing to the longevity and reliability of the product.

5. Quality Control Once manufactured, every batch of turnbuckles goes through rigorous quality control measures. This includes testing for tensile strength, durability, and dimensional accuracy to ensure compliance with industry standards.

Applications of Turnbuckles

Turnbuckles find applications in a variety of fields. In construction, they are used to brace structures, tension cables, and hold panels in place. In the marine industry, they provide the necessary adjustment for rigging on boats and ships. They are also prevalent in theatrical rigging, aerial arts, and event staging, where tensioning ropes and wires is critical for safety and aesthetics.

Sustainability and Innovation

As industries evolve, so do the manufacturing processes. Many turnbuckle supply factories are now incorporating sustainable practices, such as recycling materials and reducing waste in production. Moreover, advancements in manufacturing technologies, such as CNC machining and 3D printing, are beginning to influence the production of turnbuckles, making the process more efficient and allowing for customized solutions.

Conclusion

In conclusion, turnbuckle supply factories play a vital role in the production and distribution of this essential hardware. By understanding the manufacturing processes, applications, and innovations within the industry, we can appreciate the craftsmanship that goes into creating these simple yet crucial devices. As industries continue to grow and evolve, the demand for high-quality turnbuckles will undoubtedly remain significant, encouraging factories worldwide to adapt and innovate continually.