News

Zář . 22, 2024 23:48 Back to list

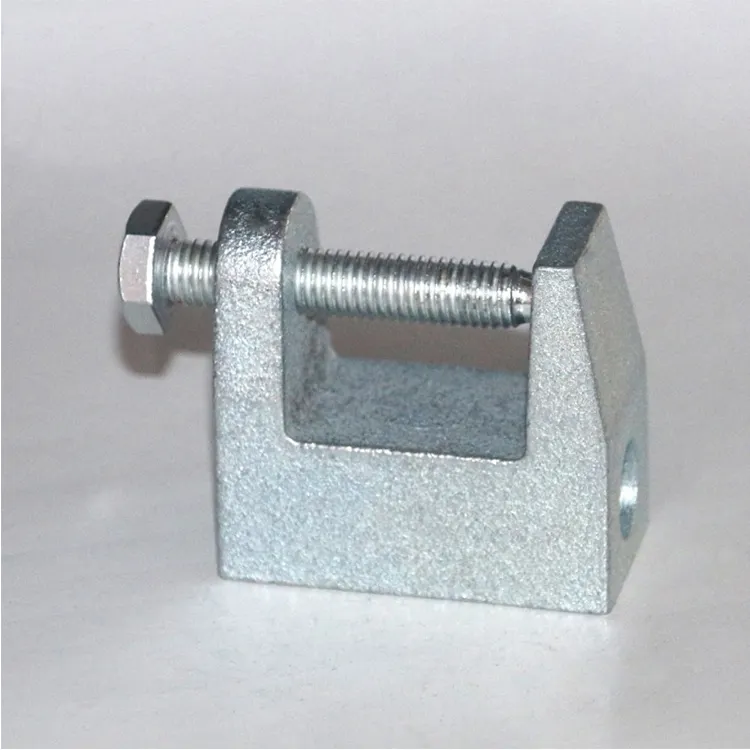

shoulder eye bolt manufacturer

The Importance of Quality in Shoulder Eye Bolt Manufacturing

Shoulder eye bolts are a crucial component in various lifting and rigging applications. They provide a secure point for attaching lifting devices, ensuring the safety and efficiency of operations in construction, manufacturing, and other industries. As a shoulder eye bolt manufacturer, the commitment to quality and innovation is essential to meet the diverse needs of customers.

One of the core functions of shoulder eye bolts is to distribute the load evenly, reducing stress on the bolt and the object being lifted. This capability is particularly important in heavy-duty applications where failure can result in significant losses, both in terms of property and human safety. Therefore, a reputable manufacturer must adhere to rigorous standards in terms of material selection, design, and production processes.

High-quality materials are paramount in the manufacturing of shoulder eye bolts. Most manufacturers opt for carbon steel or stainless steel due to their excellent strength-to-weight ratios and corrosion resistance. Using subpar materials can compromise the integrity of the eye bolt, leading to potential failures. Consequently, manufacturers should prioritize sourcing materials from trusted suppliers and ensure they meet international specifications like ASTM or ISO standards.

The design of shoulder eye bolts also plays a pivotal role in their performance. An effective design should ensure that the load is applied in the correct manner, minimizing the risk of deformation or breakage. Engineers often utilize advanced modeling software to simulate real-world conditions, identifying potential weaknesses before production. This level of foresight not only enhances the quality of the product but also fosters a culture of safety within the industries that utilize them.

shoulder eye bolt manufacturer

Moreover, the manufacturing process itself should be outfitted with the latest technology. Automated machinery coupled with precise engineering leads to consistent quality and reduces the likelihood of human error. Regular inspections and testing are integral components of the manufacturing process, ensuring that every batch meets the predetermined standards of quality and performance. Techniques such as magnetic particle inspection or ultrasonic testing can be employed to detect any internal flaws, providing an added layer of safety.

Customer feedback is also valuable for shoulder eye bolt manufacturers. By being responsive to the needs and experiences of clients, manufacturers can continuously improve their products. Engaging with customers not only fosters trust but also allows for innovations that can lead to new product lines or improvements in existing designs.

Lastly, a focus on sustainability can also set a shoulder eye bolt manufacturer apart. Implementing eco-friendly practices in sourcing materials and managing waste can appeal to a growing demographic of environmentally conscious consumers.

In conclusion, shoulder eye bolt manufacturing is a complex process that demands high standards of quality at every stage. By focusing on top-notch materials, innovative design, advanced production methods, customer engagement, and sustainability, manufacturers can ensure their products not only meet industry standards but also exceed customer expectations, ultimately contributing to safer lifting and rigging operations across various sectors.