News

nov . 13, 2024 07:28 Back to list

Факторияҳои намудҳои turnbckle

Custom Turnbuckle Types and Their Factory Uses

Turnbuckles are essential components in various applications that require adjustment and tensioning of ropes, cables, or chains. These devices come in various types and are widely used in different industries, from construction to marine applications. Custom turnbuckles can be designed to meet specific requirements, ensuring optimal functionality in their intended use.

Types of Custom Turnbuckles

1. Open Body Turnbuckles These are designed with an open body that allows for easier adjustment. They are ideal for applications where frequent tension adjustments are necessary.

2. Closed Body Turnbuckles Unlike open body turnbuckles, closed body variants provide a more secure and compact solution, which is particularly beneficial in environments where space is limited.

3. Swage Turnbuckles These types are used in applications requiring a high degree of strength and durability. They are often swaged onto cables, making them a permanent solution.

5. Marine Turnbuckles Designed to withstand harsh marine environments, these turnbuckles are often made from stainless steel or other corrosion-resistant materials to ensure longevity.

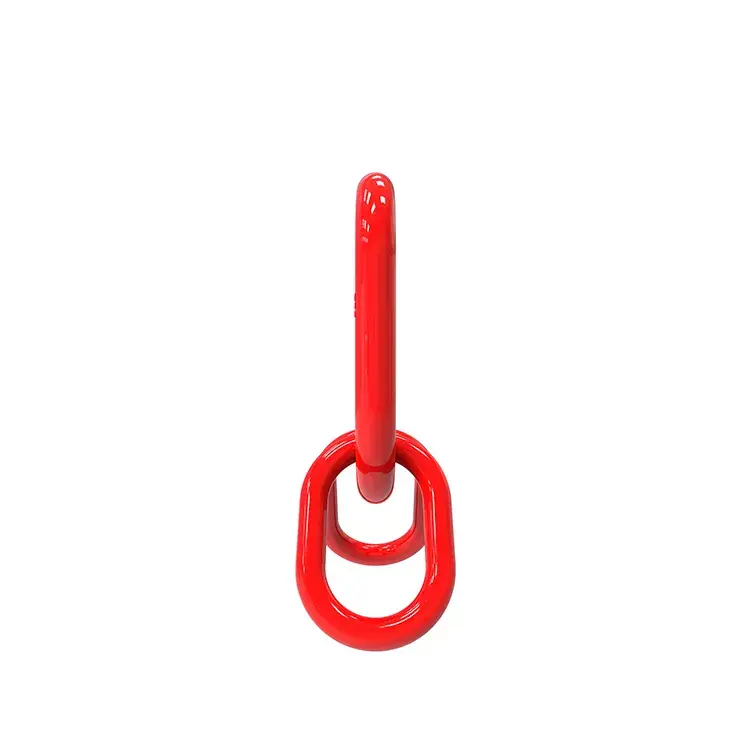

custom turnbckle types ues factories

Factory Uses of Custom Turnbuckles

In manufacturing, custom turnbuckles are vital for ensuring safety and reliability in various structures. For instance, in the construction industry, turnbuckles are used to adjust and maintain the tension in scaffolding, ensuring workers' safety at heights. They are also used in concrete forms to secure panels and maintain their stability during the curing process.

In the marine industry, custom turnbuckles play a crucial role in rigging sailboats and ensuring the masts are properly tensioned. This not only affects the performance of the vessel but also its safety on the water. Marine turnbuckles are specially designed to resist the corrosive effects of saltwater, extending their lifespan and maintaining their functionality.

The Importance of Customization

The ability to customize turnbuckles is essential for many applications. Factors such as size, material, and type of thread can be tailored to meet the specific needs of a project. For example, in construction, a project may require larger turnbuckles to handle greater loads, while a smaller application in a marine setting may only necessitate compact turnbuckles.

Customization also extends to the finish of the turnbuckles. In environments where aesthetics matter, such as in decorative installations, a certain finish might be required. Whether it’s polished stainless steel, painted, or coated with a specific material, custom solutions ensure that the turnbuckles not only function well but also fit the overall design.

Conclusion

Custom turnbuckles are invaluable in various industries for their ability to provide tension and stability in structural applications. Their diverse types and the potential for customization make them suitable for both heavy-duty and aesthetic applications. Factories that specialize in manufacturing turnbuckles play a crucial role in ensuring that these components meet the specific needs of their users, enhancing safety and functionality across many sectors. Whether for construction, marine, or specialized applications, investing in custom turnbuckles can significantly impact the efficiency and safety of operations.