News

дек. . 24, 2024 01:52 Back to list

supplier jaw&jaw turnbuckles for sale

Exploring the Importance of Supplier Jaw and Jaw Turnbuckles for Sale

In the realm of construction, manufacturing, and rigging, the need for reliable, durable, and efficient fastening solutions cannot be overstated. One such solution that has gained significant attention in recent years is the jaw and jaw turnbuckle. This article delves into the importance of these fastening devices, their applications, and what to consider when purchasing them from suppliers.

What Are Jaw and Jaw Turnbuckles?

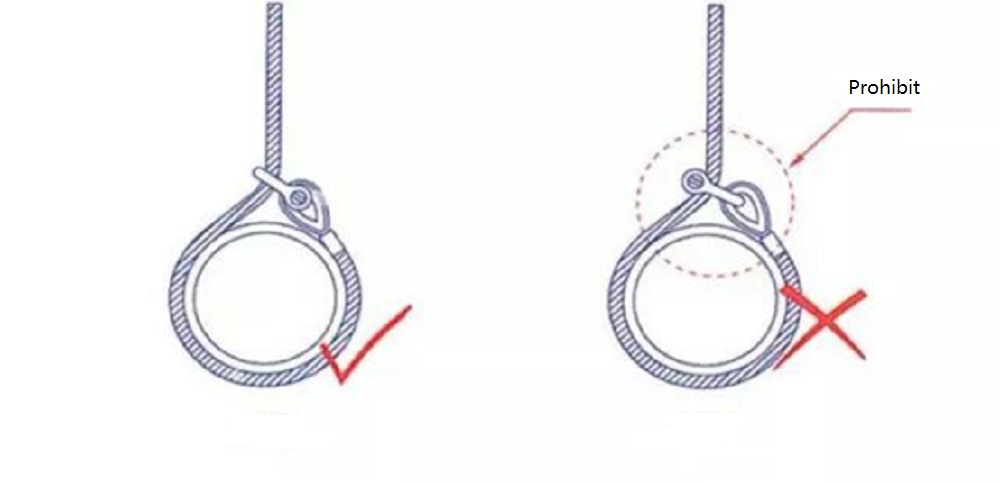

Jaw and jaw turnbuckles are devices used for adjusting the tension or length of ropes, cables, or other tensioning systems. They consist of a central body that is threaded on both ends with jaw attachments on each side. Typically, these jaws can connect to other components like hooks, rings, or other types of fasteners. This design allows for easy tension adjustment, making it an ideal choice for various applications, such as marine rigging, construction, and theatrical setups.

Applications of Jaw and Jaw Turnbuckles

Jaw and jaw turnbuckles are versatile tools used across multiple industries. In the marine sector, they are commonly employed in rigging sails and securing frames and structures. Their ability to provide stable tension makes them essential for ensuring safety and structural integrity on boats and ships. In construction, turnbuckles are often used to support scaffolding and maintain tension in guy wires, making them vital for ensuring the stability of temporary and permanent structures.

Moreover, in the world of events and entertainment, jaw and jaw turnbuckles play a crucial role in setting up stages, lighting, and sound equipment. Their adjustable nature allows for quick modifications to accommodate different setups, ensuring that everything is securely in place.

Considerations When Purchasing Jaw and Jaw Turnbuckles

When looking to purchase jaw and jaw turnbuckles, it is essential to consider several factors to ensure you obtain the right product for your needs

supplier jaw&jaw turnbuckles for sale

1. Material Turnbuckles are available in various materials such as stainless steel, carbon steel, and aluminum. Stainless steel is favored for its corrosion resistance and strength, making it ideal for marine and outdoor applications. In contrast, aluminum might be suitable for lightweight requirements.

2. Load Capacity Each turnbuckle has a specified load limit. It is crucial to assess the expected loads and choose a turnbuckle that can safely accommodate them. Underestimating the required load capacity can lead to catastrophic failures.

3. Jaw Size The dimensions of the jaws play a vital role in the turnbuckle's compatibility with other components. Ensure that the jaw sizes match the connectors you plan to use.

4. Threading Type Turnbuckles come in different threading designs, such as right-hand and left-hand threads. Understanding the application requirements will help in selecting the appropriate type.

5. Supplier Reputation When sourcing jaw and jaw turnbuckles, consider suppliers who have a strong reputation in the industry. Reviews, certifications, and adherence to safety standards are crucial indicators of quality.

6. Cost While budget considerations are essential, remember that opting for cheaper alternatives may compromise safety and durability. Finding a balance between cost and quality is key.

Conclusion

The jaw and jaw turnbuckle is a vital component in various industries, providing the necessary tensioning solutions to ensure safety and reliability. With their wide range of applications, understanding the critical considerations when purchasing them will lead to more informed decisions, enhancing not only the quality of the projects but also ensuring safety throughout their execution. As you navigate the landscape of suppliers for jaw and jaw turnbuckles, prioritize quality, material, and reputation to make the best choice for your needs. Whether in marine applications, construction, or entertainment, investing in reliable turnbuckles will pay dividends in both safety and performance.