News

сеп. . 25, 2024 11:28 Back to list

Custom Lifting and Rigging Equipment Solutions for All Your Needs

Custom Lifting and Rigging Equipment Optimizing Safety and Efficiency

In the world of heavy lifting and rigging, customized equipment is essential for ensuring safety and efficiency on job sites. Industries such as construction, manufacturing, and shipping frequently rely on specialized lifting and rigging solutions tailored to specific tasks. This article explores the significance of custom lifting and rigging equipment and its impact on operational performance.

One of the primary advantages of custom lifting and rigging equipment is enhanced safety. Standard equipment may not always suit the unique requirements of a particular job. Custom solutions can be designed to address specific load capacities, weight distribution, and rigging configurations. This ensures that the equipment meets the exact needs of the task at hand, reducing the risk of accidents and equipment failure. When workers are confident in the reliability of their tools, they can perform their tasks more effectively.

Additionally, custom lifting and rigging solutions can significantly improve efficiency. Off-the-shelf equipment may lead to delays due to improper fit or insufficient load capacity. Custom equipment allows organizations to streamline operations, as it is engineered to maximize performance and minimize downtime. For example, a tailored lifting system can simplify complex rigging maneuvers, enabling quicker and safer lifts. This not only saves time but also reduces labor costs, as fewer workers may be needed to complete the same tasks.

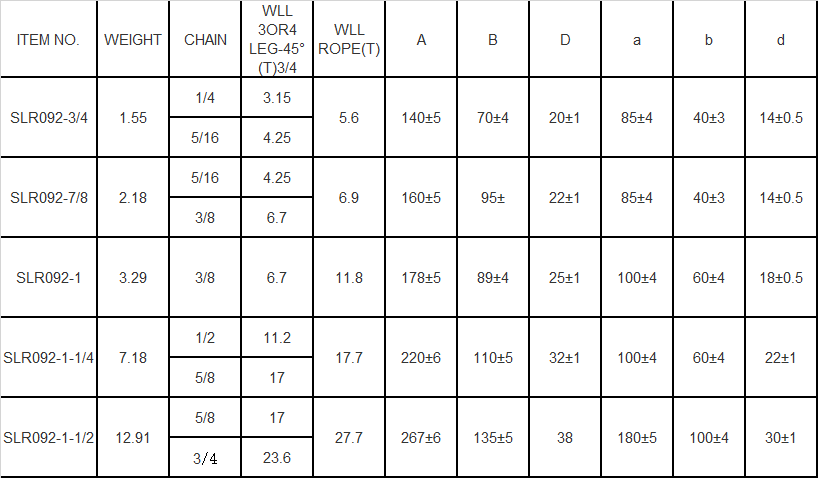

custom lfting rigging equipment products

Designing and manufacturing custom lifting and rigging equipment also offers the flexibility to incorporate the latest technologies. Advance materials such as high-strength composites and smart sensors can be integrated into the design for improved performance monitoring and load management. These innovations can enhance the overall functionality of lifting systems, ensuring they meet industry standards and regulatory requirements.

Furthermore, collaborating with specialized manufacturers can lead to ongoing support and maintenance. A dedicated supplier can provide training for staff on the best practices for using custom equipment, as well as regular inspections and maintenance to prevent wear and tear. This proactive approach to equipment management not only extends the life of the rigging gear but also maintains safety standards on-site.

In conclusion, investing in custom lifting and rigging equipment is a strategic decision that can yield significant benefits in terms of safety, efficiency, and innovation. By addressing the unique challenges of specific jobs, businesses can enhance operational performance while minimizing risks. As industries continue to evolve, the demand for specialized lifting solutions will only grow, underscoring the importance of tailored equipment in today’s fast-paced work environments.