News

Ліст . 27, 2024 07:04 Back to list

Suppliers of Various Turnbuckle Types for Your Rigging Needs

Understanding Turnbuckle Types and Their Suppliers

Turnbuckles are essential hardware components used in various applications to adjust tension, lengthen or shorten cables, and secure structural elements. They play a pivotal role in industries such as construction, marine, and sports. Understanding the types of turnbuckles available and knowing where to source them can greatly enhance their application in diverse projects.

Types of Turnbuckles

Turnbuckles come in several designs, each serving specific purposes. Here are some of the most common types

1. Hook Turnbuckles These types feature hooks on both ends and are predominantly used in applications where quick adjustments are essential. Their design allows for easy attachment to cables, chains, or ropes, making them ideal for temporary structures like tents or stages.

2. Eye Turnbuckles Equipped with eyelets on either side, eye turnbuckles are perfect for securing wire ropes or cables. They provide a strong hold and are widely used in construction and rigging applications where stability and strength are critical.

3. Jaw Turnbuckles These turnbuckles include jaws on both ends, allowing for easy attachment and detachment. They are frequently utilized in marine applications, as they are robust and can accommodate significant amounts of force.

4. Stud Turnbuckles Featuring threaded ends, stud turnbuckles are designed for applications requiring a robust means of attachment. They are commonly used in heavy-duty environments, such as in structural engineering, where high tensile strength is necessary.

5. Threaded Turnbuckles These turnbuckles are characterized by their fully threaded body, allowing for fine adjustments of the tension or length. This versatility makes them suitable for a variety of applications, ranging from light rigging to extensive structural support.

Choosing the Right Turnbuckle

When selecting a turnbuckle, there are several factors to consider

- Material Turnbuckles are commonly made from stainless steel, galvanized steel, or plastic. Stainless steel provides excellent corrosion resistance, making it suitable for marine applications, while galvanized steel is preferable for outdoor use due to its enhanced durability.

turnbuckle types suppliers

- Size and Load Capacity It's vital to choose a turnbuckle that can handle the required load. Manufacturers usually provide specifications regarding the load capacity, which should be thoroughly reviewed to ensure safety and performance.

- Purpose Understanding the specific application is essential in choosing the right type of turnbuckle. For instance, low-tension applications might only require hook turnbuckles, while high-tension structures might necessitate the strength of jaw or stud turnbuckles.

Finding Turnbuckle Suppliers

Many suppliers and manufacturers specialize in turnbuckle products, providing various types to suit specific needs. When searching for suppliers, consider the following

1. Reputation Look for suppliers with a good reputation in the industry. Customer reviews and testimonials can provide insights into their reliability and product quality.

2. Product Range A supplier offering a broad range of turnbuckle types and sizes can be advantageous, especially for businesses that require customized solutions.

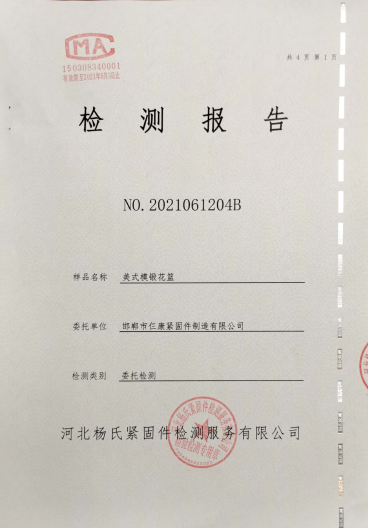

3. Quality Certification Quality assurance is paramount in safety-critical operations. Suppliers who provide certification for their products ensure compliance with industry standards.

4. Pricing and Availability Compare pricing from different suppliers, but remember that the cheapest option isn't always the best in terms of quality. Additionally, assess their inventory levels and lead times for product availability.

5. Support and Advice Suppliers who offer technical support and guidance can significantly ease the purchasing process, particularly for businesses that may be less familiar with the specifics of turnbuckles.

Conclusion

Turnbuckles are vital components in a vast array of applications, providing crucial tension and support. By understanding the different types available and identifying reliable suppliers, customers can ensure they choose the right products for their specific needs, ultimately enhancing the safety and efficiency of their projects. Whether in construction, marine operations, or sports design, investing in quality turnbuckles from reputable suppliers is key to successful outcomes.