News

снеж . 17, 2024 16:54 Back to list

shackles truck use product

The Importance of Shackles in Truck Use A Comprehensive Guide

When it comes to transporting heavy loads, whether for commercial purposes or personal projects, the safety and reliability of your equipment are paramount. One crucial component of this setup is the shackle. Often overlooked, shackles are indispensable in ensuring secure attachments between different elements of a load, making them an essential part of truck use.

Understanding Shackles

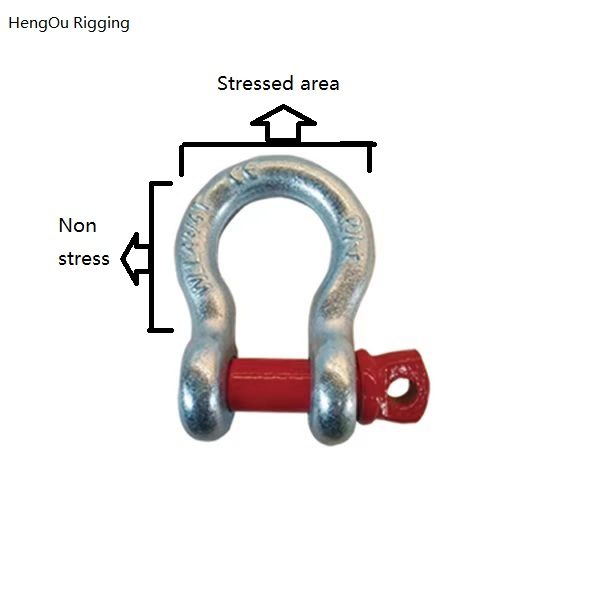

A shackle is a U-shaped metal connector with a pin that can be tightened to secure two points together. Typically made of high-strength materials such as steel, shackles come in various shapes and sizes, each designed for specific applications and load capacities. The most common types of shackles include D-shackles, bow shackles, and screw pin shackles, each offering different levels of strength and versatility.

Applications in Truck Use

In the context of trucking, shackles are used in multiple scenarios. One primary application is in towing and recovery operations. When an off-road vehicle or a truck becomes stuck in mud or snow, using a shackle allows for a secure connection to the towing vehicle. This guarantees that the process is effective, minimizing the risk of equipment damage or failure during extraction.

Additionally, shackles are vital in securing loads on flatbeds. When transporting items that could shift during transit, shackles are used to connect straps or chains that hold the cargo in place. This prevents movements that could lead to accidents or losses during transportation. Properly securing loads with shackles ensures compliance with transport regulations and enhances the safety of both the driver and other road users.

Selecting the Right Shackle

shackles truck use product

Choosing the appropriate shackle for your trucking needs involves understanding the load requirements and the environment in which it will be used. Load capacity is crucial; each shackle has a Working Load Limit (WLL) that indicates how much weight it can safely handle. Exceeding this limit can lead to failure, endangering both people and property.

In addition to load capacity, consider the material and finish of the shackle. For instance, stainless steel shackles offer excellent resistance to corrosion, making them ideal for maritime or wet environments, while painted steel shackles may provide enhanced protection in less demanding conditions.

Safety Considerations

While shackles play an essential role in truck use, users must adhere to safety protocols to ensure their effectiveness. Regular inspections should be conducted to check for signs of wear, deformation, or cracking, as compromised shackles can fail under pressure. Operators should also be trained in the proper use and installation of shackles, ensuring that they understand the importance of securing connections and adhering to load limits.

Furthermore, it is essential to match the shackle type with the specific application. For example, bow shackles offer greater flexibility for connections, while D-shackles are best for environments where space is limited.

Conclusion

In summary, shackles are a small but mighty component of truck use that should not be underestimated. From facilitating safe towing and recovering operations to securing loads during transportation, they play a pivotal role in the safe and efficient movement of goods. By understanding their applications, selecting the right type, and following safety protocols, truck operators can enhance their operational efficiency and ensure the safety of their loads on the road. Investing in quality shackles is not just a choice; it's a necessity for anyone serious about safe trucking practices.